-

Posts

1,347 -

Joined

-

Last visited

-

Days Won

22

Derek last won the day on January 19

Derek had the most liked content!

About Derek

- Birthday 01/02/1954

Previous Fields

-

Car type

2B plus

-

Full name

Derek Overfield

Contact Methods

-

Website URL

http://

Profile Information

-

Gender

Male

-

Location

Kirby Bellars, Melton Mowbray, Leics

Recent Profile Visitors

24,541 profile views

Derek's Achievements

Wheely good builder! (4/6)

161

Reputation

-

The weather is looking favourable so its a GO for today. Please let me know if you are intending to join us so I can book a table.

-

We are hoping to meet up at the Welland Valley Garden Centre Café at 12:00 noon on Monday for lunch and gossip. Welland Valley Garden Centre Café Glaston Rd, Uppingham, Oakham LE15 9EU We will be agreeing on a go/no go on Monday morning around 09:30 based on the weather forecast. Please look here before travelling.

-

Just over a month to go. At the moment its just three cars for lunch, possibly four, for the run. Is there any more interest? Venue to be confirmed depending on numbers. Please reply if you wish to join us for lunch.

-

If it ran well for 5 hrs before being modified, I would suggest you look at the things you have changed rather than looking for a new problem. It sounds like it could a bad/ intermittent earth somewhere, perhaps on the ECU wiring.

-

Thanks for organising Al. That garden centre has a cracking café good food at reasonable prices. Looking forward to the next one, perhaps a tad warmer would be good if you could organise that too Al!

-

Entries for this years Stilton Run are now open HERE On the top of the entry form it states.... The entry form is currently unavailable. Entries will be accepted from January 2nd I have been in touch with the organisers and the entry form is working fine, just ignore the message. If you are interested in having lunch please reply to this post. I will see how much interest there is and organise lunch somewhere. Happy New Year. Cheers Derek P.S. We are registered.

-

Hi IanS, The zips were supplied by Chris, the expert, who makes all sorts of covers for boats etc. My zips are all covered by flaps so they are not exposed directly to rain or standing water and the roof is sloped so the rain runs off to the front when still or the back when moving. As the back is open to the elements when its parked outside I have a separate cover for those occasions. Thanks for the compliment and your comments; I too hope it encourages owners to use their cars more.

-

I put the awning rail on the top of the screen surround. The curves I made by cutting a piece if wood, the same thickness as the awning rail, to the same radius as the screen surround. Mounting that between 2 larger pieces of wood so they would act as a guide. Then heating the rail and pulling it around the shaped wood. I must have put something into the groove of the rail to stop it closing up but I cannot remember what it was, perhaps a spring of some sort. Chris, the expert, stitched the coax into a separate folded over piece of material, about 4in wide. Then Stitched that onto the main body of the roof. https://www.attwoollsmanufacturing.co.uk/product/330g-m²-acrylic-canvas-pu-coated-150cm-fabric/

-

OK, just spoken to Chris and he says..... 330g/m² Acrylic Canvas PU Coated. Which seems to be a bit heavier than the one you are looking at. But as you say its not too expensive to try. I would suggest you look seriously at fitting a caravan awning rail to the top of your wind screen. I tried poppers, lift the dot, etc and never got a successful seal.

-

Hi Andy, I'll give Chris at Topps Tarpaulins a ring and find out for you.

-

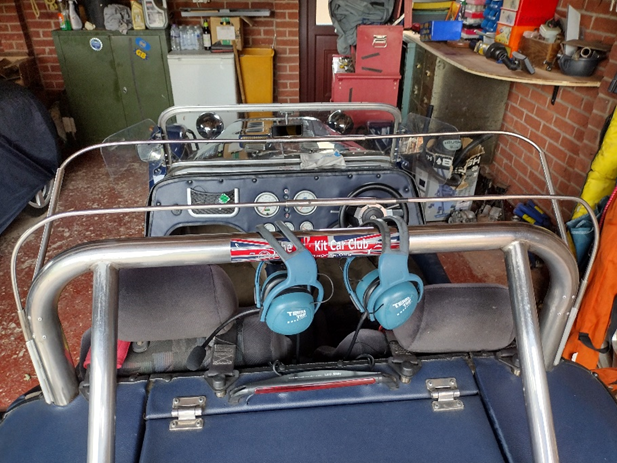

How to stay alive after soaking your wife. I have been on a quest to have a useful roof and doors for my 2B for a few years, I think I’m at a point where I’m satisfied its as good as it gets. Not watertight but it seems to keep the worst of the weather out. I fitted the RH weather protection initially but with the doors on I found it far too claustrophobic and not really rain proof. I guess I was short of patience to persevere with it and therefore the result was not what I wanted. I went to a show and one of the RHOCaR members had a “Surry” roof on his car, asking where he got it from, he replied, I make them. Beer tokens were exchanged, and I was a proud owner of one. There were a few ideas that helped me on my way (journey) to where I am now with this roof, but it was still lacking in a few areas. The roof used the same fastenings as the RH wet weather gear and the water came in between the roof and screen. I was still using the RH doors and they did not meet the roof at the top and there was no where to store them in the car. With doors off the water kicked up by the front wheels when I was turning right ended up in my lap, most embarrassing upon exit! Worse still during left turns the water ended up in my wife’s lap, don’t ask! So first on the list was a solution to the wheel/water problem. I had seen a couple of cars with ½ screens on the bottom half of the “door” opening. I made a paper template that I thought would work and was off to see Chris at Topps Tarpaulins who made them a reality. They solved a couple of problems; there is hardly any water coming in from the wheels and they keep a lot of the draft off on long journeys on A roads and motorways. Having solved the wet pants problem my attention went to the roof. Using the bought one as a template I was again at Chris’s discussing how it could be made better. I had seen cars with caravan awning rails fitted to the windscreen and we decided this was a good solution. Arial coax cable and the thickness of the material proved a great fit but still slides in easily. Next subject under discussion was how to stop the roof wearing out the hair out on the top of my head, it’s sending me bald. I found some stainless bar and tube which fitted the new purpose. The bar was bent to suit, and an angle bracket welded together to provide some over the head support. As everything must go in the boot, I cut the hoops in half and used tube to join the halves together. The old roof had a hoop over the roll bar held on with bathroom bolts with the bolt taken out. OK time for a copy. B&Q have just the thing, 2 purchased, modified and pop riveted onto the roll bar. The next thing to consider was how to fasten the roof at the back. Fastened to the roll bar supports these seemed to be the best solution and have worked very well. This photo also shows the “all in the boot” rule being followed. Ok I now had a fully functioning roof the doors were next on the list. Previously I had taken the old doors apart and cut metal frames in half so they would go behind the seats (new rule all in the car!) I dismantled the doors completely and using CAD (cardboard assisted design) set about redesigning the frames. I kept the front metal forms as they would be correct for the new design. The rear top one needed modifying because the top of door would be longer the bottom one would remain the same or similar. Some bar steel was purchased and the whole lot was welded together. Chris again covered them and welded in the window. The material acts as the hinge between the top and bottom halves. I will come back to the doors in a bit. Everything is going swimmingly well until we went out with the doors on and found the bottom half would flap up at any speed over 30mph. Not good, see wife getting wet! I came up with this temporary solution that has been in place for ?? years. At the same time, I put on a tab that would hold the door closed. This was OK but the roof and the doors tended to separate once under way which was annoying me. A rethink was needed. Over to see Chris again and discuss solutions. We decided to put zips along the top of the doors and inside the roof. I had to go away and think about this as how would I be able to do the zips up once I was inside or conversely on the outside. Chris said you can have double zips that do up from both sides, problem solved. I had my roof, doors, and half doors to suit every occasion. This was great for a few years but eventually time catches up with you or more exactly your body. I have had two replacement knees which seem to have reduced my height by one inch, long story, I’m still 6’3” so folding up to post myself through the gap between the roof and the bottom of the door became an ordeal; unless the weather forecast said absolutely no rain forecast the car stayed in. Whilst out with the East of England bunch someone (apologies I cannot remember his name) had a Zero with the roof on and it had an access zip which gave much more room to get in and out. Its copy time again. Over to see Chris yet again, can you do something like this? “No problem” he said. The result is that we can get in and out much more easily. It has taken a lot of time, much mental acrobatics, skinned knuckles, and a bit of cash, but I am happy with the result and can enjoy the car for a few more years. Oh and the best result my wife is reasonably happy but she does still monitor the weather forecast. If you want any more detail of the process, please contact me (Derek) through the RHOCaR website. Happy motoring.

-

Craig Stirk started following Derek

-

-

OK OK hint taken I'll put one on after the mag is published!

-

Keep an open mind towards making your own. If you do they will be exactly what you want. I don't want to spoil the article.