-

Posts

3,753 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Grim

-

I've had a few alternators do this, I think it's heat related damage as it's close to my exhaust. Eventually the output drops completely until it wont take the load of headlights etc and I replace it. I've now moved it further away, haven't driven it enough to say it solved the problem though.

-

I've replaced all the fuel hose on my car this year, partly due to age but I made sure to buy decent hose to replace it. I ended up buying cohline r9 (e85 compatible) hose as it wasn't too much extra. Aside from the rubbers/seals issues, the remainder of the material issues I see are from the corrosion of certain metals due to the slightly hygroscopic nature of the ethanol content. I'd be tempted to flush the car through with a tank of super if the car is going to be stored for any time, but if the car is in occasional use I would think the fuel should not absorb too much water in this time.

-

If it's similar to the pinto, it's probably caused by the the idle air control valve being stuck - try removing it and cleaning it out as a first step.

-

You'll have to take the head off and measure the chamber volume. Be aware that there are also low compression pistons in former transit engines which are stamped on the top.

-

a round piece of pipe formed around the cap to prevent access to the sharp edge?

-

How did you connect the trailing arm hard line to the caliper flexi hose? I'm currently making some brackets to fit to the bearing housing, but wondered if you found a better way. I would have welded something onto the arm, had I realised I needed one before I painted it!

-

I think mine must be an intermediate design between the two, it's got splayed (horizontally, but vertically fore and aft) bars in the centre of the dash, but the dash tube meeting the bonnet. Go with the above advice

-

Burton might be a good option. https://www.burtonpower.com/oil-filler-cap-x-flow-pinto-etc-fp630.html

-

mine has no gap, the mid-bonnet flanges are trimmed back to clear the dash-top tube. If there's a gap there, isn't there also a gap between the bonnet and side panels? That can't be right can it?

-

Have you got a wiring diagram to show that the speedo wires go to the ECU? I haven't got a later haynes manual to check. I would be surprised if it needed the speedo output to do this as the pinto eec iv system can manage this with the throttle position/engine speed information alone.

-

what engine are you using? If it's pinto with the eec iv, it wont be interested in the speed, the sensor was only for the speedo. What speedo do you have?

-

Is it possible the plugs are wet because of a poor spark causing a misfire? Oxidation / dampness in the rotor cap/arm, or dirty/damp ignition leads. Clean the ht cap (and oxidation of the terminals in the cap), rotor arm and leads etc. Check out the air flow meter wiring by backprobing the connectors in the ecu as per the instructions in Derek's post. Looks like you should measure 0.5 to 4.8v over pins 25 and 46 (or maybe 25 and 43?) when the vane in the AFM is moved. I'll have to check the diagram in the haynes manual - I've got scribbled notes in my manual I've made from when I did it last. Also check out any earth connections, there are a few in the engine loom. Whenever I've seen problems with overfuelling it's been AFM related - but running was very lumpy and it was spitting out plenty of soot.

-

Does the exhaust smell rich/fuelly or sooty? Have you looked at the air flow meter? is there anything preventing movement of the vane inside?

-

cut the bottom off the existing valve to remove the mechanism, or buy an elbow from burton: https://www.burtonpower.com/breather-elbow-sohc-pinto-681f-x-flow-pre-x-flow-20mm-fp280.html

-

The only real reason to do this is to avoid IVA. Why avoid IVA? Apart from the modest one off cost, it implies to me the car is not capable of passing an IVA, ie built poorly or potentially dangerously. I know we are all likely to make iva-incompatible alterations to our cars once built, but a car that's not broadly capable of passing an IVA should not be on the road, and I wouldn't buy one without committing to the work required to bring it up to standard

-

Alan, How do you know the temperature reading is correct? If the fan does not come on until some time later, and that is controlled by a separate switch, doesn't that tie in with the temperature gauge over reading?

-

I found a voltage drop on the column switch feed wire from the fusebox, which I've temporarily replaced and it pretty much solved the problem.

-

I've been doing a bit of work of the car lately, in an attempt to fix some obvious mot fails. One is the rear tail lights flashing with the indicators. Due to a myriad of crappy corroded crimp connectors, corroded wiring etc, I've replaced the light wiring back about 6 feet, replaced the light housings (I had replacements in stock, purchased in 2010!) but still the issue persists. I've fed in a secondary earth from the lights to the chassis and from chassis to battery with no change. Putting a voltmeter on the tail light feed shows the voltage fluctuates as the indicator flashes so there's obviously some resistance upstream of the lights but within a common feed from the battery. I've removed the fuses and wire brushed them (pretty grotty) and that has reduced the voltage fluctuation from 1.5v down to 1v. My plan for tonight is to do the same for the indicator stalks, lighting relays and battery isolator. Is there anything else I should look for? Andy

-

does anyone have a pair, or even just a passenger side trailing arm, suitable for disc brakes/lobro joints? I've stripped mine down and they need welding at a minimum, but thought I'd look on here to see if anyone has any in better condition. Andy

-

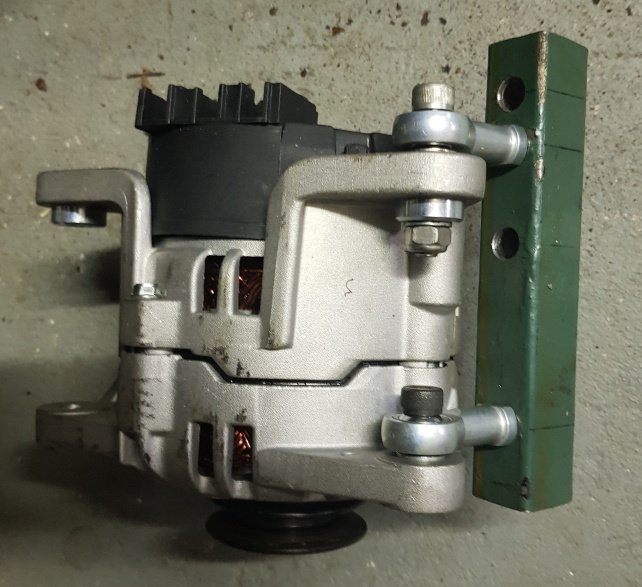

I've got around to fitting the alternator - it seemed like an almost direct swap for my old alternator, but I wanted to drop it a bit lower to move it away from the exhaust, so I made some new brackets to utilise the bottom alternator mounting holes on the block rather than the top ones. Pulley was a direct swap from my old alternator. rose jointed bottom bracket bakewell aided design top bracket progress top bracket finished fitted. I've ordered a shorter belt to give a bit more clearance to the steering column. Andy

-

David I'm in chesterfield if that's not too far?

-

I still have these wheels, free for any member who wants them

-

Any takers for a September meet at monks bridge farm on Wednesday the 2nd? The weather still looks ok for an outside meet. Andy

-

I can't really resist at that price, will have to see if i can make it work with the single V pulley and my mounts. I'll have to get some time in the garage to work on the car as i've not touched it in 3 years!