-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Nicholas M Walker

-

I purchased a Robin Hood S7 a couple of years ago as a running project and have been chasing engine gremlins pretty much from day one. The engine is a 1.6l Pinto from a 1983 Sierra - not massively potent but plenty fast enough from behind the wheel! Initially there were issues with the dirty fuel affecting fuelling, so I rebuilt the fuel system with an electric pump, fitted a new 32/36DGAV carb and had it setup by a good friend of mine. Unfortunately the issues remained and persisted even when I replaced coil, rotor arm, distributor cap, leads and plugs - the car would start and run, accelerate OK but would always 'stutter' and misfire in the mid-range when trying to hold a given speed. Given that there wasn't much else to try, I bought a Powerspark Electronic Distributor kit - unfortunately this turned out to be useless with my engine. After a bit more invstigation, I have finally pieced together the story - so if you're sitting comfortably I will begin! My engine was fitted with a Bosch JGFU4 distributor - a factory fit item with inductive discharge system and vacuum advance. I won't go into the full detail of exactly how the inductive discharge system works but basically there is a metal 4-pointed 'star' mounted on the distributor shaft, a static disc with four posts within the body and wire coil to generate the magnetic field. When correctly setup, the four points of the rotating 'star align with the four posts in the body when the rotor-arm is aligned with the No. 1 mark on the edge of the body. The 'star' itself is made up of two parts, an inner steel collar that goes over the rotating shaft and which is located with a small steel pin, and the outer 'star' which is an aluminium pressing. These two parts are then pressed together. Unfortunately, this distributor also has a bit of a design flaw - with the Distributor Cap removed the clips used to secure the Cap onto the body have a tendency to drop inside and catch on the edge of rotating star. This means that if you bar the engine over with the Cap removed, it is posible to damage the rotating 'star' so that it goes out of alignment. Having taken my distributor apart, this had happened - the 'star' was out of position by about 10 degrees! I have attached some pics which show the spider in the actual and correct positions - there is a locating pin which sits in a groove in the side of the shaft and the inner part of the star. Another telltale sign of this issue was that the leading edge of the rotor arm tip was clearly burnt, a sign of serious arcing occuring because of the offset between the inductive discharge system and the actual firing position of the engine. Again, I have attached some pics showing the damage to the rotor arm. Following discussions with Jonny Best @ Bestek Crawley, I have been able to remove the original 'star' from the rotating shaft (carefully) and am now awaiting a replacement item to complete the rebuild. I hope that this is of interest to some of you - I will post more pics once this is completed and hopefully wrap-up this issue once and for all.....!

- 1 reply

-

- 1

-

-

OK - so does anyone know how Robin Hood allocated chassis numbers? Were they numbered by RH or were they allocated locally by the builder or Test Station when they were first registered?? I have a Sierra 7 with a chassis number ending 000000000001......! Is this actually the first one produced?

-

Does anyone know if there are any events planned in the North West region coming up? I am based in Cheshire, so would love to meet up with other RHOCAR members in the North Wales/Cheshire/Lancashire/Greater Manchester areas if anyone is up for it?

-

Mr Toad, The pressure regulator was the return type - original equipment on the early Sierras from which my kit was built. I have (for now at least) re-plumbed the fuel system so that the output from the pump goes directly to the carb inlet and I can confirm that I am now getting fuel to the right places. Unfortunately it now seems as though I'm not getting a spark, so will replace the coil pack and see whether this brings the old girl back to life. My other concern is that given the location of the distributor on this engine (directly above the fuel pump) and the age of the wiring I may have accidentally damaged one of the wires going into the body of the distributor. I can't immediately see/feel any damage but that doesn't mean it hasn't happend inside the insulation.

-

Nigel, I am very interested in your use of the Facet Pump without the pressure regulator, have you had any issues with excessive fuel consumption? I bought a Robin Hood with a 1983 Sierra 1.6 engine earlier in the year and it appears that the original bypass type pressure regulator has failed - replaced the pump and still can't get consistent fuel flow to the carb (a Weber DGV 32/36). I have read the original Haynes manual for the donor car, which indicates that the pressure regulator is there to balance the output from the mechanical pump with the requirements of the carb. In other posts (on the Marlin owner's site I think) other people have said that they have bypassed the pressure regulator and connected the mechanical pump outlet directly to the carb inlet without any issues but I am a bit nervous of this as a solution, as I understand it can cause leaking through the top-hat seals in the carb. Any thoughts/advice would be much appreciated...!

-

Not a member of nwkcog but sure I read something in the club booklet I received when I joined up here. Is the meeting at the Stretton Fox an open thing - would I be welcome to come along in June??

-

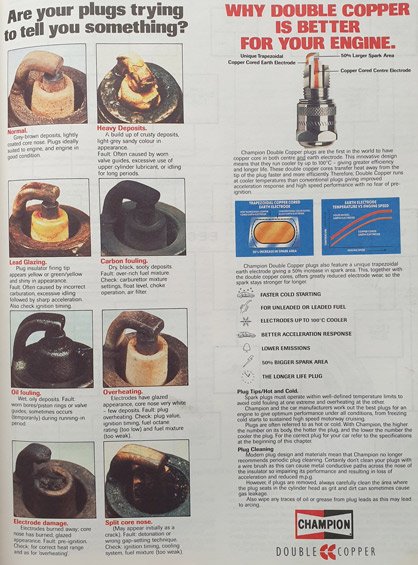

nickp - I have a Robin Hood Sierra S7 (recently acquired) so I've been getting to grips with the Pinto engine - mine is only a 1.6l not a 2.0l but from what I understand they are all derivations of the same thing. I managed to get hold of the Haynes Manual for the Ford Sierra doner car - it has been very worthwhile! The no.1 cylinder is the one nearest the timing belt (front of the engine in your pics/vids) and the firing order is 1-3-4-2 if that helps. I have had a very similar issue with the engine revs dropping if I floor the throttle - mine is on a Weber 32/36 DGV twin-choke carb. It got to the stage that I could only keep the car running with the choke fully open, even with a new fuel filter element. I took the decision to strip and re-build the carb - it was very worthwhile as there was an enormous amount of crap in all the places it shouldn't be. Having refitted the overhauled carb, it runs a lot better than it did and the issue with the pick up on throttle demand has been significantly improved but not totally elminated. I have purchased a new Powerspark electronic distributor, coil, leads and new plugs and will be fitting these in the next few weeks - I am hoping that this will prove to be the final part of the solution. Your fuel filter does look like it could do with a change - with the paper element filters if there's enough crap in there they can collapse under hard acceleration and starve the carbs. You might also find, as I did, that the inline fuel filter was a later addition and that enough crap had already got into the carbs to affect performance. Also, given that there is effectively a carb per cylinder, there might be issues with the balance between the air/fuel mix but I must admit that I am not an expert on bike carbs. Finally, having had a look at the images of your spark-plugs I would say they look pretty much OK - have a look at the guide in the attached picture which is extracted from the Haynes manual. It might be worth gapping them just to make sure the electrode gaps are right - if they are Champion F7YCC the gap should be 0.8mm (0.032") or if they are RF7YC they should be 0.7mm (0.028"). Obviously I can't tell what type they are from the pics - I'm not that good!!

-

I am new(ish) to the club and live in north Chehsire. I think I read in the club booklet that I received when I joined that there was a monthly meeting in the Warrington area on the first Wednesday of the month. Does anyone know whether this still happens and if so confirm the location, I would be interested in making the next meeting if I can.

-

Thanks theduck - I assuming that these fit on top of the hub, with the McPherson strut dummy insert passing through the hole in the flat plate. Has anyone got a phot of these in-situ of their car for reference? I certainly won't be buying a set from Kitspares at that price but I will use that as the basis for my own design!!

-

I have the cycle wings but not the stays - did you fabricate yours or are there stays that work with the Sierra hub/suspension arrangement on the S7?

-

Interesting theduck - am only in Cheshire so it might be worth a meet-up to compare setups?

-

Thanks to theDuck for posting my original enquiry on here and thanks to the rest of you for comments. I believe that I have misunderstood what the car I bought is - I have the original bill of sale from Robin Hood Engineering Ltd, dated 12th November 1994. It describes the kit as being a 'Robin Hood Sierra based kit' with a fully welded stainless steel body/chassis. I have not had the chance to drive the car as much as I had hoped, partly because the weather has been crap but also because I had to completely rebuild the carb as it turned out the inline fuel filter was very much a later addition! Once I had it apart, there was dirt in almost every place it wasn't meant to be - since it went back on the car has been significantly better! I have purchased the Accuspark distributor and coil kit but have not had the time to fit it. I have purchased a Type 9 gearbox and the cycle wings - I just need the time to design the wing stays to suit the Sierra front hubs and make the changes. I'm not certain now whether to update the engine, it seems wrong given that it's a Sierra based kit to use a more modern lump although I am thinking of upgrading to a 2.0l Pinto if I can get hold of one.