-

Posts

8,200 -

Joined

-

Last visited

-

Days Won

70

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Longboarder

-

Having a constant earth on the negative/switching side of the coil will work fine. No sparks. Very little risk to the coil but it could overheat if ignition was on for half an hour. Still mch cheaper than having the car stolen.

-

Current practices change with the years. Mine was SVA in May 2000. Mine states in special notes . 1. Non transferable registration mark. 2. was registered and/or used. Declared manufactured 1985.' No record of emissions anywhere on my V5C. Pre SVA kit cars may have been registered as Sierra or Cortina but V5C was supposed to be updated when new legislation came in later around the time of SVA but pre IVA I think. Any kit still registered as sierra is wrongly registered. Amended. Done more reading on the web and come across many cases of wrongly registered kit cars correcting the V5C with DVLA. (Also some which have had to undergo SVA/IVA.) So it's possible to correct the V5C but it is several weeks of hassle with DVLA, possible inspection and presenting evidence (like old photos, tax discs, service records, MoTs, etc) that prove the pre SVA history of the car.) Perhaps correcting emission standards is also possible.

-

Type bosch wiper motor 0390216054 into ebay. Lots of modern, front wiper motors with similar looks to yours. (modern + front = two speed and five wires). Once you know some of the cars that have similar wiper motors you could hunt your local scrapyards clutching your old motor for comparison.

-

My VVT pro was bought direct from ME just before they sold it to TriggerWheels, and has been problematic although it does seem to still work, but only in 2D mode. (Advertised as 3D.) The software is in my opinion something out of the 80's. Very clunky. Seems to refuse to do and confirm changes in the map but when I next drive the engine note changes where I have made the map changes so it does seem to have accepted them, even though the software says it hasn't. I have had zero support from ME. I'm not convinced Trigger wheels understand it either and they have no obligation to me anyway. I couldn't recommend buying an ECU from ME due to my opinion of the poor quality of their software and lack of interest/assistance/customer support, although I have had no experience of the ME100. Haven't spoken to them for 3 years so they may have changed. If I was going for VVT control again I would upgrade my Omex 600 to any of the quality brands that included proper cam control, such as Omex or Emerald.

-

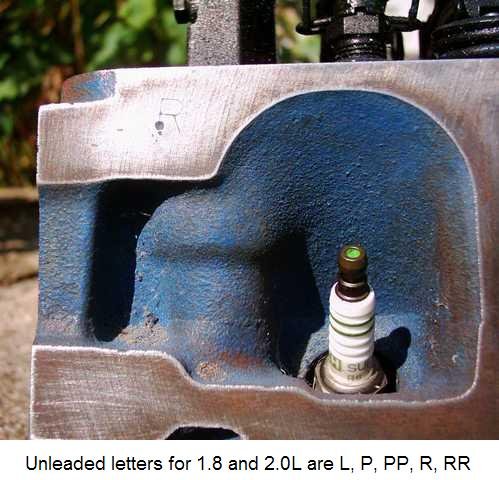

A 'leaded engine' runs fine on unleaded petrol although the lower octane level will require ignition retarded a couple of degrees but suffers valve seat erosion which of course will eventually cause a compression drop and running problems. It is possible this has happened and if yours doesn't have hardened valve seats then a compression check would be worthwhile. Cylinder heads with valve seats for unleaded were stamped with letters on the exhaust face close to spark-plug number 4. See pic below. Letters for 1.6 are M, MM, N, NN. 1.8 are S, SS. 2.0 are L, R, RR, P, PP.

-

Tuned pinto needing a more reliable electronic spark. The aftermarket choices must be powerspark or accuspark both of whom can supply a distributor for about £100. You can tell them current/future mods to the engine so they can provide the ideal advance curve built in. They may specify an ideal coil as well. Very simple to fit and reliable. Only an ECU controlled 'non distributor' ignition system with mappable spark tables will do better such as megajolt from someone like Trigger-wheels but more expensive of course and will need mapping on a rolling road for perfection.

-

I have to disagree with you there. Thermostats are simple and amazingly effective devices that have been around for a hundred years and remain the cheapest most effective and efficient way of maintaining the engines operating temperature within relatively narrow parameters. The design of the cooling system is also important to avoid air locks and allow proper flow of coolant. The thermostat flow control also allows the fitting of a radiator with sufficient heat exchange capacity to cool in hot weather when driving hard without over cooling in subzero winter days. I wouldn't want to drive without one.

-

Basic problem is the water rail. Designed to took good but ignores the problems remote thermostats bring and the install instructions do not suggest using a header tank (or they didn't when I bought one years ago). Having the stat 9inches down a blind tube with no flow is not a great plan so you have to create flow. Hole drilled in the fixed part of the stat and I would suggest 5mm diameter is the best solution. Fill, run up to temperature and keep topping up as you run the engine with occasional rev-ups for 10 minutes. Addition of a header tank is also a good thing. If it doesn't self bleed air under these circumstances the cooling system has other flaws. The raceline rail is much better designed, cheaper but not so blingy. The original stat housing works perfectly and the raceline one saves less than an inch of space in comparison. (My blacktop stat housing cannot be removed with the engine in situ but I can change the stat in situ.)

-

The ESC11 with DFTH carb that went with it are a bit clunky and overcomplicated. If you have a poor running engine then changing to an accuspark dizzy and converting the carb by removing the stepper motor and making up a screw type 'throttlestop' to allow you to set idle will simplify matters. This will only help if you have checked through the usual culprits for poor running like cam timing, compression, air leaks, ignition timing, dizzy components, leads, plugs, jets, fuel supply, float height etc and they are all ok. What carb are you using?

-

ESC11 and its Bosch 'Hall Effect' dizzy are already electronic, albeit with a more conservative ignition map than say Accuspark. The ESC11 also controls manifold heater and the stepper motor on the carb for idle control. Is there a problem with the unit? Changing to accuspark would be unlikely to give big gains but is perhaps a little more adjustable. I ran ESC with twin 40's and it was fine.

-

True it's not a good design creating the potential for air to gather in the hose but flow is pretty vigorous at that point which reduces the effect. You could have a look at the hose length. Cutting an inch off each end of the hose will lower the rear arm of the hose that attaches to the stat housing but not the arm on the radiator. Further you may be able to raise the radiator a little. I would also have a look at the gearbox mount under the rear of the box if it's a type 9. Raising that by mounting it above the floor rather than under it will drop the front of the engine and it may be able to be shimmed up even further without problems. Probably not much you can do to lower the engine mounts without endangering the sump but make sure they are not shimmed up. Is the sump already shortened?

-

Do you mean you have a bent tie rod/track rod. Probably best to replace it and you get the bonus of a new inner ball joint and they are not expensive.

-

Plug colours do suggest its running rich, not greatly but differently in each cylinder. Are all the plugs the same type. 1 & 2 look as if they are running less rich or hotter than 3 & 4. I think the carbs need a strip and clean, resetting of float chambers, checking needle positions (might be the type of carbs that allow different needle length settings) and balancing carefully. If that doesn't sort it then I would be hunting a bike carb expert for advice.

-

Brilliant set of pics and vids. I was not expecting bike carbs which are great once set up. Lumenition ignition with a modified bosch dizzy. The fuel regulator you show is a fuel pump. Worth having a good look at the blue cap. There will be white letters on it, 12v and a part number. The part number is critical as to its pumping pressure and you can look that up on the HARDI website to check its low enough for bike carbs. Afraid there's a big hole in my knowledge of bike carbs but plenty here who know lots. That's a grubby old filter of the correct type so could do with a change. I would check timing with a strobe on the crank pulley and clean the dizzy. Remove and check the plugs and probably refit them. Their colour should tell you a lot about how rich or lean it's running. I would pull one of the fuel hoses from the filter and run it into a milk bottle and switch on the ignition to confirm good steady fuel flow. Check cam timing if you can. I suspect those will all be OK. Then it's down to the carbs and you I can't advise on those. Overall I think its a nice if very untidy set-up which has loads of potential. I expect there is a hot cam in there to go with the bike carbs. A tidy and clean , a bit of carb tuning and it will purr.

-

Perfectly plausible guesses above. Could be any one or something else but this ideally should be a dialogue. Questions and answers both ways works best. You have a 2.0pinto with an unknown carb, unknown ignition system and unknown fuel pump that is a poor starter, spluttery unreliable idle and hesitation on sharp acceleration. What ignition system, what carb and what pump if I may ask? A pic of the left side of the engine bay to show those items would do. I would start by checking ignition timing and fuel pump output to eliminate those before concentrating on the carb checking and tuning. And I wouldn't waste money on buying new bits in a scattergun approach before making an attempt to identify the problems.

-

Not electrically shielded enough? HT interference generation is greater when accelerating. Bigger spark needed. Check the rev counter wire is shielded and the shielding is earthed at only one end of the wire. Check you are using suppressed HT leads. Check the shell of the rev counter is earthed.

-

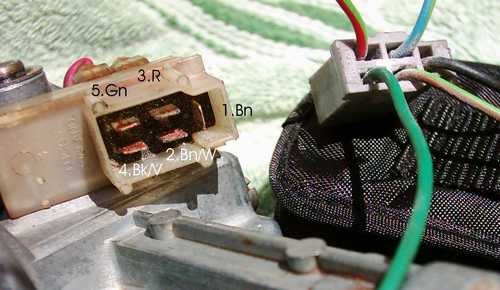

So, confirm a lucas two speed motor. The pictures I posted previously are from that type of motor. The brush plate is. The other view of the five pin plug is too. It does sound as if you need the white park switch box. The three leads you have can be connected to the sierra column switch but without the park switch box you will not have wiper parking. IVA fail. But if you want to go ahead without the yellow lead connects to 53B, the red lead connects to 53 and the black to any earthing point on the car. I can't guarantee those colours. You can look at your brushplate and work out which of your wire colours does what. But I would advise you to buy a park switch box and fit it.

-

-

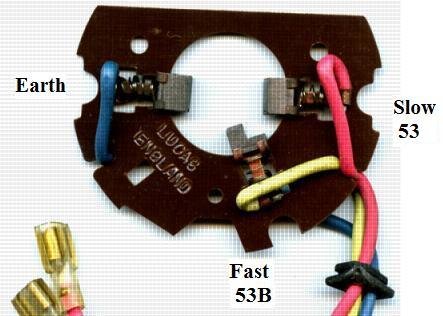

Sounds like you have a motor with the brushplate wires only and no connecting plug/park switch. It is a usually white plastic housing with five terminals. The 3 brushplate wires go to pins 1,3,5 in the back of the plug. Park switch is 2, 4, unwired on the back. It sits on the surface of the crank and gear housing. You can make out some of it in the pics below. One shows the brush plate and it's 3 wires, red (slow), blue (earth) and yellow (fast) in this case and the other shows the plug and part of its white housing sitting on the motor.

-

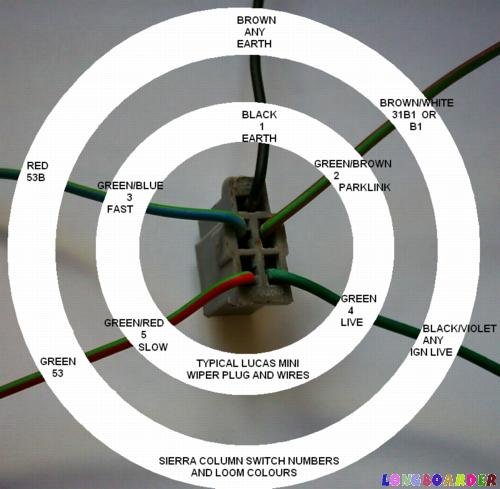

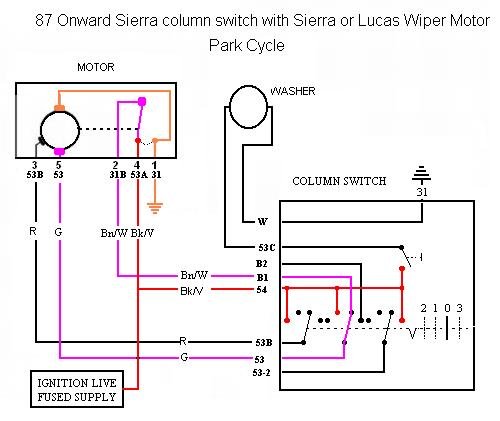

Never ceases to amaze me the bl88dy awful wiring diagrams on reputable sites. Here is a labelled pic of a Lucas wiper plug. Of the two label circles the inner one are typical lucas wire colours and Lucas wiper motor pin numbers and the outer label circle are sierra wire colours and sierra column switch pin numbers. If this isn't enough there is a more diagramatic style wiring diagram which is shown with the ignition on but the wiper has just been switched off and is part way through its park cycle. The red bits are live from the ignition but are not supplying via the switch. Instead the red supply to pin 4 on the lucas motor (pin 53A on sierra motor) is feeding back current along the lilac path, out of Lucas pin 2 (sierra pin 31B) through the switch and back out to pin 5 on the Lucas motor (pin 53 on a sierra motor) to run the park cycle. When the wiper motor reaches the park position a cam in the motor breaks the connection between lucas pins 4 & 2 (sierra pins 53A & 31B) and the motor stops with the arms neatly parked.

-

Yes, matched units one would hope. But I don't think hope quite cuts it. Ophidr hopes his engine runs no doubt. That hope is not getting him anywhere at the mo. So you resort to checking components, wiring, maps, configurations, sensors. When I first installed my omex ECU they couldn't provide a sensor map for the zetec ford temperature sensor. So I did my own. Buckets of hot, warm, cold, iced water, a kettle, and accurate thermometer and some time. Eventually I had a graph of sender output against temperatures 0 to 98. Wrote it into the software and it continues to give accurate readings to the ECU ten+ years on. I initially used some bosch sierra cosworth injectors (low impedance I found out after I had bought them) with ballast resistors but they still 'broke down' at 4000rpm on a rolling road. Switched to high impedance without ballasts and they worked fine. Probably would have run without but Fuel injection is the sum of its parts. Commonly it's not one problem but a number of minor snags. So you try to get as many things as possible spot on. I don't assume something I can test is functioning till I have tested it. Fuel pumps. You can measure fuel pressure. Is it what the ecu thinks it is? Etc. I'll stop.

-

Do you have a Bosch part number for the injectors. I can look up and see flow rate and impedance values. Emerald needs high impedance injectors. Original white zetec injectors are high impedance.

-

Good point Bob. I don't know if ether will ignite on compression in a petrol engine. Ophidr 's problem (or problems) are clear as mud! Needs a housecall to check from basics. Configuration of ecu? Does it match configuration of sensors, configuration of maps and wiring of car. Bosch injectors. High or low resistance? Flow rate? Why not use the zetec ones? Like trying to do a jigsaw puzzle. Don't even know if he has all the pieces. Hands on is the only way to find the problems IMO.

-

Easy start sprayed into each intake has resulted in 4 hot exhausts. This suggests that each cylinder is getting a spark at roughly the right time and is capable of firing the easystart/air in it. So ignition fault now moves much lower down the list. Air and easystart is obviously getting in and the mixture is getting enough compression to fire so mechanicals are working OK. So it would seem to point to fuel not getting in to cylinders 3 & 4 when you are trying to start so I'm thinking somehow injectors 3 & 4 are not firing or not firing properly. I'm now stuck as I don't know emerald, how you have programmed the injectors to fire (sequential/batch), how you have wired them up. For a simple eyeball check on this suspicion I would remove the air filter, prop the butterflies wide open, grab a good torch to peer down each intake and try to start the car. You should be able to see the injector in each throttle body spraying fuel into the engine. Hopefully well enough to see a definite yes or no and even compare if they are all reasonably similar. If this simple test shows lack of fuel going into 3 & 4 then at least you will know where to hunt the fault.

-

And there was I thinking you were using an emerald zetec start up map with all the parameters set to your engine configuration.