-

Posts

2,268 -

Joined

-

Last visited

-

Days Won

93

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by alanrichey

-

I wish they would list them so we could buy what we think we might need. At the moment it’s guesswork.

-

I've just ordered one. Cheaper than 2 new front tyres And yes, to adjust camber you have to break the top ball joint.

-

Looks good, but I did note this on one of the sites: Please note: Trackace requires a minimum of 100mm under vehicle ground clearance so for low vehicles it may be necessary to raise the vehicle by placing suitable blocks under the wheels. Is that a problem ?

-

I haven't heard of any Superspec not fitted with the MT75 (LHD Granada model). Was the gearbox actually different or was it the release arm ? And I don't think the turbo aspect makes it any different.

-

OK, it seems Chris simply handed in the original clutch plate and pressure plate and that is what he was given in return. So there is no explanation as to why a different clutch plate was used. Sorry, not much help.

-

Stoneleigh - National Kit Car Show 28/29th August 2021

alanrichey replied to Danielle's topic in Events

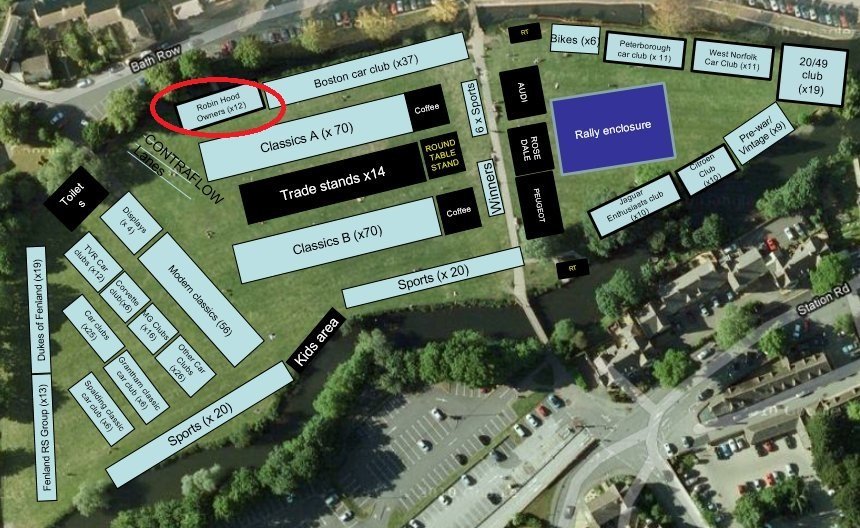

OK, ignore previous post. I just did a side-by-side comparison of the site map and the (old) Google Earth shot. They have certainly lost a lot of room with HS2, it's going to be quite cosy if a lot of people turn up. In previous years I have never strayed up to the band stand area so that will be new. I see the kit car entrance is labelled 'Main Gate' (as against 'Main Public Gate'). But in previous years the road has been closed in front of Exhibition Hall so getting to the Band Stand area could be a bit of a challenge. Looks like take second right just before the Westfield drift then first left and then right at the T-junction. I think I will follow someone else -

Stoneleigh - National Kit Car Show 28/29th August 2021

alanrichey replied to Danielle's topic in Events

Although I have been there a few times I am having trouble matching the site map to my memories of the layout. Has it changed completely because of HS2 ? And there is no sign of a kit car entrance, which we always had in the past. And I don't remember a band stand. So very confused -

I’m afraid I don’t know, I am just passing on information I was given by Chris. However the clutch plate and release bearing are not connected in any way so I don’t see why not. I’ll ask him why he went with separate items.

-

Got my confirmation this morning. I see they have moved our Club stand back to our usual place just by the entrance. So it's going to be a busy weekend, Stoneleigh on Saturday then Stamford on Sunday . I will aim to get there between 09:00 and 09:30. Hope we have a decent turnout (and decent weather)

-

That was what made me wonder if the clutch cable had seized. Although mine have never seized I have had one get so stiff it was almost impossible to move. Hence my suggestion you see if the release arm still had movement in it. Although I accept that if the release bearing has jammed somehow that the release arm would still have movement. Just making sure you eliminate the 'simple' answers before you make the big step of dropping the gearbox. Also, you should be aware that I don't know anyone who has managed to release the gearbox without dropping the engine as well. I suspect that after removing the prop shaft and the bolts holding the gearbox to the mounting plate you won't be able to move the gearbox back far enough to get it out. I await your attempt with great interest, as if it works that makes life much simpler As to the rattle, we still don't really know what is causing it. If I was doing it I would try and get hold of a proper MT75 release arm and bearing. Again, I have no idea why Richard didn't use the official one. Maybe when he bought the gearboxes they didn't come with a release arm of release bearing so he decided to save money by making his own bearing and fitting any release arm he could find. Or maybe the proper release arm was too long to align the cable with the hole that was drilled in the mounting plate. We are in undiscovered territory here In an ideal world it would be nice to run the engine while it is out, to test if the rattle has been fixed, as it would be annoying to have to drop the engine/gearbox again to try a different attempt. Not sure how you do that, maybe just connect the sensors up without using any of the engine mounts when the body is first dropped down.

-

I take it you have eliminated the cable as the failure point ? Can you still rattle the release arm or is it seized ?

-

I've asked him to post the details, alternatively he is on Facebook, Chris Mccormack. However, I have found some information that he sent me: Clutch Plate - Use EXEDY MZK2100 - £100 Pressure Plate - This is slightly confusing as he quoted LUK 623 3350 00. But when I googled that I got the full 3-piece clutch kit - £135. My spare clutch pressure plate has URB10009 0215 stamped on it so that is another option to search for. Release bearing - While you have it apart you might as well try the official MT75 release bearing. Google 500 0071 10. However there must have been a good reason why Richard made up his own bespoke bearings, I just don't know why. But at £20 it's worth a try. I will be interested in how you get on, my belief is still that the release bearing is meant to clip into the release arm, and ours aren't, hence the rattle. Let me know if you need any more information. I would also like to know how you manage to lift the car up

-

I know someone who has just changed his clutch and can tell you everything you need to know. Not sure he’s on here so I will get him to post a reply. Alternatively ‘wanderer’ has also just done his clutch so he might reply.

-

Hi, welcome to the Club. Unfortunately there doesn't seem to be an Area Secretary covering Cambridge. Perhaps you need to volunteer ? If you look at the Member map you will see there are 3 members relatively close to you. Jago, Gav888 and Leslie Walters. Might be worth Messaging them.

-

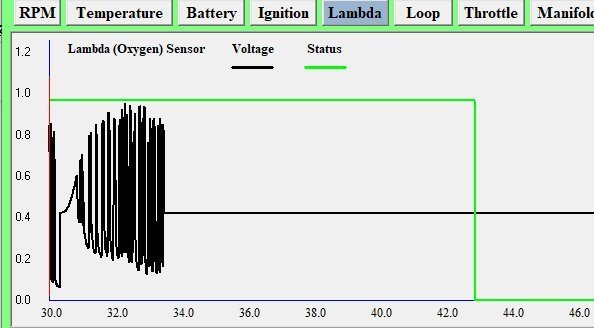

As it turned out there were only 2 of us so we just went and sat under the trees at Burghley House and talked kit cars My car started to run like a pig on the way home. Easy to diagnose when I looked at the trace of the lambda sensor in my log file: When I looked underneath. The lambda sensor wiring had come adrift and was scraping on the road. Soon one of the joins gave up the ghost. Quick fix

-

Not sure the cat is relevant here ? Like you I assume it is the CO we are talking about which needs to be below 0.3 As I understand it the CO level is to do with the mixture which should be controlled by the lambda sensor. The purpose of the cat is to clean up the hydrocarbons and they were not mentioned. I agree we need a lot more detail. As an aside, having struggled with emissions during the early years, I blocked one of my exhaust outlets (a Superspec-specific design, not relevant to a normal 2B) then every year I add an injector cleaner to the fuel tank one fill up before the MOT and do a 40 min run just before the MOT, doing it all in 3rd gear so the revs sit around 4000+ rpm. It's worked for the last 3 years, with straightforward passes

-

And very relaxing it was too, just watching the boats and chatting (it was at the junction of the Grand Union and the River Nene'). Now the weather seems to have started to settle down we intend to make the most of it. Our next meet will be next Wednesday lunch time. We haven't decided where to go yet, so it will be a surprise

-

Weather has been against us for the last few days but it looks to be getting better. So for a first one we are going to go for a picnic lunch at a village called Wadenhoe on the River Nene on Tuesday . Anyone that wants to join us let me know.

-

I would have to disagree with that I think. The fan is there to prevent the engine overheating, so my logic would be that you want to be monitoring the hottest part of the system. Otherwise you could be getting cylinder head damage while the output from the bottom of the radiator is still within limits. So I have my switch in the top hose. However I have to admit that the original switch on the Superspec was built into the bottom of the radiator (it uses a rad from a Rover SD1), so maybe I’m talking rubbish

-

That was how it was designed by the original owner You are right of course which is why some keen owners fit auxiliary electrically driven water pumps as well. to maintain circulation while the fan is running. I have found by experience that it seems to cool off a bit quicker if the fan stays on for a bit even though it is only the radiator being cooled, but maybe I am imagining it. So it's really personal choice, but if you go to a kit car meet and line up with the others you will find quite a few of them are gently humming to themselves long after the owner has left.

-

I had an incident where I turned on the override switch and the dash light came on but unknown to me the fan did not turn on. Luckily it was cold day so I didn’t actually need it. So make sure you wire it so it actually tests for the fan running and not just that the switch works. My fan has a permanent 12V feed and a switchable earth and the 12V supply had failed. But the light had a separate 12V supply so came on when the earth switch was made. You also need to decide if you want the fan to run on after the engine has stopped (This is what I have). If so then it is a direct battery to fan feed. If not then the 12V feed needs to come via the ignition switched 12V supply and will then probably have to operate via a relay.

-

It’s come already. My local Sainsburys has changed over. Interestingly it’s price for super, which is still E5, is about the same as other garages are charging for ordinary unleaded, which is E10, so I shall probably still go (I have a Rover engine so there is no guidance)

-

It's now going to be 1200pm on Wednesday 30th at Eyebrook Reservoir. Nothing to do there, just sit and admire the view, have lunch and talk about kit cars. very relaxing

-

Depends on whether the lights are operated by a pressure switch in the brake line or a mechanical switch on the brake lever itself. Either of them could have failed 'on', or when it happened to me the mechanical switch had simply moved slightly, leaving the brake light on.

-

The next outing is planned for 29th or 30th June. Haven't decided where to go yet, looking for inspiration. Any ideas ? Anyone want to join us ?