-

Posts

392 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by AndyW

-

Yes the injectors are 12v, powered through the MEMS ECU from its 12v relay supply. The ECU earths them to control the injector pulse length. So ECU gets 12v power to pin 28 (brown/pink) from ignition relay. Then I *think* it is passed inside the ECU to the injectors as a constant 12v but I'm not sure of the wiring connections or colours. The injector pulses are then controlled by the ECU earthing... Injector 1 to pin 24 (yellow/blue) Injector 2 to pin 23 (yellow/green) Injector 3 to pin 26 (yellow/white) Injector 4 to pin 1 (yellow/black) If you're only seeing 4.5v going to injectors then that doesn't seem right. 5v is what the ECU uses for the sensors. So have you got the correct wire? And did you have ignition turned on to power the relay to pin 28? Andy

-

It might be a bit late now you’ve started painting, but I had good results with Frosts Extreme Chassis Paint in satin black. I used it to brush paint my wishbones and hubs 3 years ago and still looks good now. I was put off using hammerite smooth as reviews suggested it chipped easily and came off in flakes.

-

That wouldn’t work as there is only one wire from the sender to the gauge. There are 3 possible fixes mentioned in early forum posts: 1) rejig/bend the float arm so it operates on the other side of the sender, 2) invert the potentiometer on the sender so the float arm swipes the other way, or 3) unsolder the signal wire on the potentiometer and solder it onto the end of the coil.

-

When you replaced the fuel pump, was it just the pump, or did you replace the whole sender, float & pump? If it was the whole in-tank unit, then It’s likely your gauge is now reading back to front. As originally supplied the Superspec fuel gauge read in reverse - full when empty and vise versa. You had to swap the wires on the potentiometer to get the gauge to read correctly. Although there was an electronic Spiyda module you could buy to correct the calibration. Don’t know if the previous owner might have fitted one of those? It’s a bit difficult to tell from your photo, but the tank looks near empty to me. If it was 3/4 full you’d clearly see the petrol level a couple of inches from the top if you removed the sender unit. As Al says, you need to check your filler and vent pipes on the fuel tank and make sure there are no kinks or restrictions. I can fill my Superspec at pretty much normal speed, just have to slow down when it’s nearly full. I regularly put in 30-35litres and drive it for 200 plus miles until it gets down to a 1/4 again. The original tank takes 42 litres.

-

I had slow cranking on my Superspec with my original tired battery. It was helped by improving and cleaning all the earths. Best to have 3-way direct earth cables or straps - battery neg to starter mounting bolt, battery neg to chassis, and engine block to chassis.

-

And if he wants to look at lots of different kit cars, the Kit Car show is on at Malvern this weekend. Worth a look around if he can get to it.

-

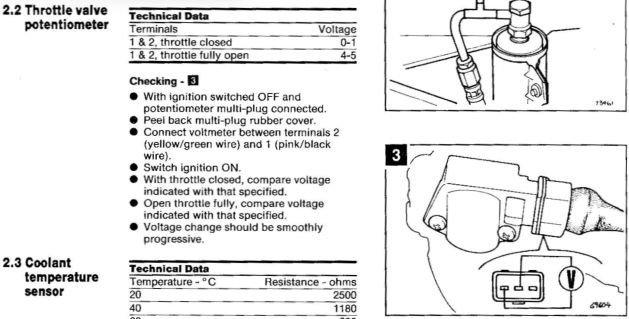

Good news on the fuel pump. On my car, the tps wiring loom connector has: Term 1 (+) is the supply. yellow/purple goes to ECU pin 9. With ign on should be 5v Term 2 (o/p) is the wipe output signal. yellow/green goes to pin 8. With ign on and throttle closed should be 0.6v, throttle fully open should be 4.3v. Change should be progressive between. ECU idle position is determined by the 0.6v closed reading. Term 3 (-) is black/pink and goes to ECU sensors earth on pin 30 So your wiring seems ok. If you don’t get those voltages then the potentiometer may be suspect. My battery is a Varta C6 Silver 52Ah which is perfectly fine for cranking and starting. I had terrible hot cranking problems with my previous battery until I determined it was duff and replaced it.

-

The fuel pressure regulator on the end of the fuel rail operates at 2.3-3bar. If you remove the return hose from it, and turn the ignition on to get the initial 1 sec pump priming, then fuel should come out of the regulator (put a container underneath!). And definitely when you crank the engine. You should be able to hear the fuel pump whirring. If no whirr or no fuel comes out then the pump isn’t working. Make sure you tightly clamp the fuel hose afterwards. If you get fuel out ok, then remove spark plugs and crank again. You will get a strong smell of petrol if the injectors are working ok. However this all assumes your crank sensor is now working correctly.

-

I agree with Al that your Crank Position Sensor looks very dodgy. The CPS trace for my engine is like Al's, on and a completely solid line as soon as the engine is cranked until turned off. The fact that yours turns on and off might indicate a problem. The CPS is fundamental to the engine running. Without a cranking signal MEMS won't know the engine is turning and won't operate the coil or injectors. From my notes, here are some things to check on the CPS: - disconnect the plug and check resistance across the 2 sensor terminals, should be 1260-1540 ohms - check the plug and wiring is intact, and all connections are making good contact - check the sensor is correctly fitted over the flywheel. It's held with 2 bolts and there should be a spacer underneath to give the correct distance away from the 34 reluctor poles on the flywheel - the 2 core cable should be connected to the engine loom with a screened and earthed cable to prevent interference - the wires should connect blue +ve to MEMS pin 31 and white -ve to pin 32 (my engine wiring colours) - the blue wire should show 5v with ignition on, and then drop to 3v when cranking

-

Yes I should have explained better. My photo shows how some Superspecs (not mine) have the fuel hoses simply pushed into the pump connectors. My car actually has the proper elbows as Al describes, though I didn’t have a clear photo to show them. I would think the plastic elbows give a more secure and rigid connection, and also have the added advantage that they reduce the height of the hoses curving above the tank and hence the risk of kinking the fuel hoses with boot boxes or anything else on top.

-

I replaced the fuel pump on my Superspec last year, which meant removing the sender from the tank and disconnecting the fuel lines. The connectors are a bit fiddly but when you work out how they operate, it's straight forward to disconnect them. Mine still seem sound after 20 years, so I've never bothered to change them, and many Fords used the same hose fittings so must be ok. The red and white collars are part of the sender body, and the fuel line elbows push into them and are gripped in place with barbed wedges. If you look closely at the collars they have sliding tangs on opposite sides which are hidden underneath the top collar mouldings. You need to squeeze both inwards at the same time using a pair of long nose pliers to release the barbed wedges. Then, while holding them in, you can pull the elbows out with a twisting motion.

-

Yes in fairness the jump leads were heavy duty so no problem there. But even with another battery connected it doesn’t mean the voltage is getting through, if there are wiring problems. It would be worth putting a voltmeter on the coil and checking that it is getting 12v or more when turning over the starter. If it’s not that would indicate a voltage drop somewhere in the system.

-

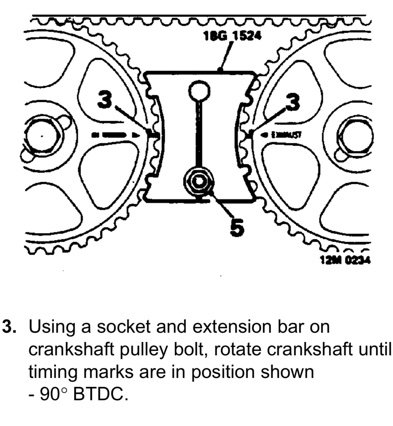

I don’t think the blue marks have any significance. The correct cam alignment when the crankshaft has been rotated to 90 deg BTDC is: left hand inlet cam sprocket should have the In mark pointing to 3 o’clock position right hand exhaust cam sprocket should have the Exhaust mark pointing to 9 o’clock ie both marks should be aligned facing the centre. You can get a locking wedge to hold them in place when working on the engine. .

-

We were getting a spark at the plugs and the engine ran, so the coil should be ok. If you've swapped the throttle body we really need to test if the TPS on that body is really working properly. We got a test output from it but maybe its not good. If you've got a multimeter and can get to the back of the wires inside the connector, here are the test details...

-

This is Wayne’s Superspec you’re talking about? The last I heard the engine was reluctant to crank and start. Did you have the battery tested to see if it was holding its charge, and check all the starter and battery earth cables and terminals as suggested? If you’ve gone ahead and removed the starter motor for testing I’m not sure why the flywheel could be stuck. There is nothing else in contact with it. Make sure it’s not in gear! You should be able to put a large ring spanner on the front crank pulley bolt and turn the engine over by hand, though not easily as you’ve got engine compression to overcome. It’s easier with all spark plugs removed. The engine should turn fairly easily then as I recall when I rebuilt my engine.

-

To be clear when you say you have starting problems, is it the starter motor only turning over slowly or reluctantly? Or does it crank ok but not fire up and run?

-

I've got a Varta Silver C6 52Ah in my Superspec. Bought it in 2018 to replace the original 12 year old battery and it immediately fixed all my poor starting & cranking issues, and is still going strong. Having said that, the original Rovers had 45Ah batteries so would have thought yours was ample enough. Check the battery earths have good contact.

-

Just to check whether it’s a vent or vacuum problem with the fuel tank you could try driving without the filler cap on.

-

I hope to be there for the Saturday, if the weather holds

-

Thanks for the offer Dave. I had a good look at Derek's Surrey top this week, so I'm probably ok on the awning rail and fixing. I'm still pondering on whether to stay with my existing press studs on the screen, or change the front fixing to an awning rail. In the 3-4 times I've had to drive the car in rain over the past 6 years, I've not found that much water comes over the top of the screen between the material seam. I'm tempted to live with the current fixing to reduce the amount of work. Also, I tend to undo 3 poppers on the edge of the windscreen and fold the roof over as an aid to getting in or out of the car. I wouldn't be able to do that with an awning rail fitting.

-

Thanks for asking Derek. So I’m on the right lines with that PU coated material. Looks like that company don’t do a 330 gsm, only a heavier weight 380gsm but that might be too thick to easily work and sew. As you suggest I was already considering changing the windscreen mount to an awning channel with coax cable in the Surrey seam to slide in. I’ve got poppers along the top of the windscreen at the moment and they do allow some water to come in over the top of the screen in heavy rain. So I could remove the poppers and either screw or bond a rail on. Just need to work out how to make the curves for the edges

-

Hi Derek, I’ve seen this material mentioned before, which seems suitable. https://www.profabrics.co.uk/products/6oz-pu-coated-nylon?variant=6809898435 A couple of meters to try won’t break the bank. And I have my existing Surrey top to use as a template, so just need cut and hem it.

-

What material did you use for the Surrey roof Derek? My new year project is to make a new one myself - if the sewing machine (and my lack of skill) is up to it.

-

Great to see another Superspec on the road. Looks good. And unusual to see the handbrake mounted on the right of the driver’s seat instead of by the passenger seat. How is the cable linkage arranged?

-

Yes, me too