-

Posts

8,200 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Longboarder

-

Adding a couple of pics to illustrate. Don't forget the rear camber shims and for a great leap forward a viscous diff. Not caterham standard but better than all the other Hoods before the zero.

-

Peter, You should remember that the 'New 111' had double unequal length wishbone front suspension, outboard shocks and springs, and no roll bar/tie bars. I ran 100 lb springs at the front. Rear coilovers mounted from the lower end of the roll hoop to the centre of the semi-trailing arm spring pan (not to the old sierra lower shock mount). At 120lb. The steering rack needs to be shimmed upward (on mine over an inch) to get rid of bump steer. The mushrooms to which the outboard end of the upper wishbones attach need to be raised about an inch also, not bolted up at their lowest position. Watch rotation of the mushrooms. In the wrong orientation the ball joint can lock up.

-

And the vent is working for sure.? Try a drive with the filler cap off. If it still happens then you need to confirm your pump is still working when the car comes to a stop. Still with the fuel cap off, whip the fuel line off the carb (not anywhere else) and lead it to a bottle/jar. Turn over the engine on the starter. You should have good spurts of fuel. (This tests the whole fuel supply line from tank pickup to carb including each component along the way)

-

Last spin on Rhocar to see if anyone wants it. The last and best performing of the Monocoques, Robin Hood New 111. Built by me in 98/99 not quite in time to avoid SVA but it was a first time Pass on 26 April 2000. Build principle was always function over form. Everything had to work best. There was a lot of Data on what could/should be modified or strengthened on monocoques and I did the lot. Front double unequal wishbone suspension. AVO shocks. 130lb springs. Rear sierra axle correctly rubber mounted, viscous LSD, AVO shocks. 13 Minilite clones, Toyo R888 Proxies. Steering rack raised/shimmed to eliminate bump steer. Shaft mounted on swivel ball bearing through bulkhead. Pedal box with twin master cylinders and adjustable balance bar. Mintex pads and shoes. Engines have been pinto, silvertop, blacktop, silvertop and finally ST170. Raceline ally sump. Jenvey TwinThrottlebodies. Omex 600 ECU. Piggybacking Mtec VVT controller. 4:2:1 tuned length exhaust with excellent collectors. Was 196 BHP on the rollers for a magazine shootout 8 years ago when it had shonky injectors. Injectors replaced but not been on RR since due to health /caring issues. OK body. Rough glass. Lives outside. Best fitting hood in the club. Doesn't leak. Good mini heater. VDO dash. ECU software on an old laptop. For the last 8 years I have been caring for a family member who has now passed on and the Hood has sat outside unused. MoT mileage each year but it does look in need of a little TLC. Spares Nosecone. Side screens. ST Engine. 'Tons of stuff. Take what you want.' Didnt sell it last winter to someone who was keen but it's only done MOT miles for the last few years and I wouldnt trust it for 200 miles. So there we have it.Very quick, well handling car to scare yourself in. Built for someone around 5'6" - 5'8". £4000.00 . Best to trailer it home and carry off what spares you want.

-

Out of interest which head are you using? Stay with VVT or standard blacktop? One of the problems when you drop out for a while. You miss developments and trends. I thought duratec stuff would be a lot cheaper by now.

-

I used a floor mounted pedal box but stuck with the cable operated clutch. 'If it aint broke dont fix it' Works fine! Personaly I would not use the ST170 head but stick with a blacktop zetec head. ST170 seemed the way to go 10 years ago when I was doing it, not many around, but these days why would you not go straight to duratec? No Brainer? Yes it was nice the standard bellhousing/type nine bolts on. New release bearing and clutch and you are in business. ECU and throttle bodies as you would expect but unless you control the VVT inlet timing properly the engine will have no power above 5000 rpm. Mine uses a piggyback second ECU for the cam. Clunky but effective. Just shy of 200 horses. I dont think these engines take well to turbo charging. Tiny exhaust valves. You might as well stick a blacktop head on it if you are going that way but the bottom end is stronger than standard zetec. It was a frustrating and expensive journey but ultimately OK but there are easier and cheaper ways to 200 HP. Go Duratec! (Or buy my car. £4000 and there's the complete kit with a very nice exhaust and a spare car!!!)

-

Wierdly I have a pair of camber wedges in front of me I bought at a show years ago. 3mm wedge difference top to bottom. No toe built in. Yours for postage.

-

Pics below.A lot of trial and error with the mounting point to tub position, length of each vertical and horizontal element and mounting point of rear shorter bar. You can get close straight off easily enough and then just cut and weld the elements to fine tune the fit. Screen position is critical. Not to far forward or back. Fit screen poppers. Then fit only the poppers across the back panel, not the sides. Then fit the frame and adjust for best look. Note tensioning between roll hoop and front bar, not between the two bars.

-

If the top and bottom tanks are still ok you can take it to your local radiator specialist and have a new core fitted. Plusses are you don't have to alter the plumbing and if you have cooling problems you may find they can fit more cores .

-

Plymouth in Devons sunny south where the rivers run with honey and there are diamonds in the streets.

-

No, sorry. Spent the last few days in various hospital departments and the rest sleeping. Absolute pain in the whatsit.They even forgot me in the waiting room at one point. Random nurse strolls over. Asks 'Who are you?' Bad sign. Anyway no sorry I haven't had the computer on much. Have replied to your message.

-

Thanks for those who remember. Nothing from those who might buy? As bad luck would have it I had a small stroke on Thursday leaving me unable to drive for a while and left arm and leg a bit weak so I can't even take anyone for a test drive. So what to do now?

-

Sadly it's me thats too old and the car too fast. I don't remember corners used to come at me so quickly. Painful but the time has come to sell. The last and best performing of the Monocoques, Robin Hood New 111. Built by me in 98/99 not quite in time to avoid SVA but it was a first time Pass on 26 April 2000. Build principle was always function over form. Everything had to work best. There was a lot of Data on what could/should be modified or strengthened on monocoques and I did the lot. Front double unequal wishbone suspension. AVO shocks. 130lb springs. Rear sierra axle correctly rubber mounted, viscous LSD, AVO shocks. 13 Minilite clones, Toyo R888 Proxies. Steering rack raised/shimmed to eliminate bump steer. Shaft mounted on swivel ball bearing through bulkhead. Pedal box with twin master cylinders and adjustable balance bar. Mintex. Engines have been pinto, silvertop, blacktop, silvertop and finally ST170. Raceline ally sump. Jenvey TwinThrottlebodies. Omex 600 ECU. Piggybacking Mtec VVT controller. 4:2:1 tuned length exhaust with excellent collectors. Was 196 BHP on the rollers for a magazine shootout 8 years ago when it had shonky injectors. Injectors replaced but not been on RR since due to health /caring issues. OK body. Rough glass. Lives outside. Best fitting hood in the club. Doesn't leak. Good mini heater. VDO dash. ECU software on an old laptop. Some of the older members will remember the car from shows and Barkstone where it was always one to beat. For the last 8 years I have been caring for a family member who has now passed on and the Hood has sat outside unused. MoT mileage each year but it does look in need of a little TLC. Spares Nosecone. Side screens. ST Engine. 'Tons of stuff. Take what you want.' So there we have it.Very quick, well handling car to scare yourself in. Does have one years MoT. £4000.00 Drive it home, enjoy it all summer and smarten it up next winter.

-

Agree to all the above for current recalibration. Are you saying the pedal only partialy opens the throttle butterfly? If so then you have extra performance potentialy available. Slight lengthening of the pedal arm to give more cable movement or reduction in length/diameter of the throttlebody arm to require less cable movement, each giving full butterfly opening could be a good plan. However changes to the emerald map would then be needed as top end airflow would be greater than currently. But free extra power? Whats not to like?

-

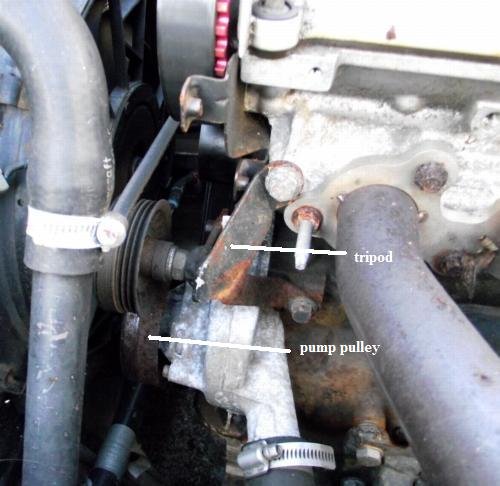

Escort/fiesta 1.6 pump. Not Mondeo 1.6 pump. My later solution (I first had a silvertop, then a blacktop then another silvertop and lastly a ST170) was to make up a three leg pedestal holding a V groove pulley and run the mondeo pump off the back of the belt. There are handy bolts or holes to mount it.

-

Another thing to check is that the ignition timing is not over advanced at cranking speed. The problem being the cylinder first firing too early slows the still upward travel of its piston. This happens on good engines when firing starts before the cranking speed is high, then all the others join in, keeping cranking speed too low. Simple test is to retard the dizzy a few degrees and see if the cranking speed improves. With earths I have an overkill three! Battery to car body, engine to battery and engine to car body, so return circuit is doubled (in case of one connection being poor.)

-

To add to the above with the escort and mondeo zetec belts, they have different belt runs. The pump is turned clockwise in the escort/fiesta 1.8 and 1.6 , the mondeo pumps 1.6, 1.8 and 2.0 (or maybe just the 2.0) are turned anticlockwise. For a simple run without idlers an escort pump works fine. Belt run can then be as below, a simple triangle. All the pumps bolt up to all the blacktop zetecs. The obvious visible difference between the two pumps is the straight exit pipe you want. The pump you have has an angled exit pipe. Pumps are 30 quid on ebay.

-

I vaguely remember that the water pump from the 1.6 or 1.8 fits straight on and turns the other way. So long since I did it I've forgotten the details.

-

Most tachos of the 60's, 70's and 80's are three wire, connecting to ground, 12v ignition live and to the 'negative/switching' side of the coil without disrupting whatever switching wiring is already in place. The switching wire may come from points, ECU, or some other electronic module. Just leave that in place and add the wire from the tacho (by convention often green) to the negative pole of the coil.

-

Zetec blacktop 2.0L bolts onto type 9 standard bellhousing and I guess is easiest but won't get to more than 180 out of the box but 200 is easy. SE/Sigma is a yamaha engine so special bellhousing needed which I guess you already have but only 160. Duratec HE I4 2.0L is a mazda engine so needs a new bellhousing but would be closest to 200 out of the box. I would probably go proper duratec if I was doing it today. Over the years I have had pinto, silvertop, blacktop, ST170.(all modified). Next step was going to be to supercharge the ST but I got too slow as I got older and the car got too fast. Most fun was probably the pinto. All sound and fury. The ST is silly. Find myself unintentionally doing 110 on a dual carriageway slip road when I just intended to get up to joining speed.

- 12 replies

-

I run an ST170 and it has been a long hard and expensive road to get to 200BHP. You will need extensive headwork, all the usual as they are crudely finished and the exhaust ports are the same size as a blacktop, ie pretty small! Without fully controlling the inlet cam, power crashes above 5000rpm. Moving to the SE1700 has all the same problems. If you are thinking of keeping to a budget then modifying the 1600SE or going blacktop zetec 2000 is easier, cheaper and you will get close to 200bhp. Just because you have an ST manifold is a daft reason to consider the engine to go with it. Proper duratec 2000 is an even easier engine to get to 200 horses and only a little more expensive.

- 12 replies

-

Well, didn't know that! Every day's a school day. Pretty sure my column was not adjustable but just been out to look and yes, there is a pinch bolt as shown.

-

This sounds like an ideal case for a home visit from local members in the Hampshire area. Probably a simple problem but the dearth of clues suggests a logical comprehensive checking process to diagnose. As it has run since rebuild it is almost certainly a simple fix. I'm 71 and currently being investigated for a neurological problem, ? Parkinsons. Distressing to start a simple job on the car and find what you did easily a couple of years ago either takes forever or you just can't do it anymore.

-

Obsessional nitpicking, but those are twin dellorto DHLA which I preferred over the webers. I'll get my coat.

-

Does your V5C give emission figure standards and if so what are they. You should be able to tell from them if you have a chance of passing without a cat.