Leaderboard

Popular Content

Showing content with the highest reputation since 07/04/2024 in all areas

-

One of our memenbers, Russ Garrett, has bought to my attention that there have been a number of scam profiles on Facebook that are targeting kit car pages GBS/ Robin hood and so on, by trying to sell parts. They ask for a deposit then disappear. When you look at the sellers profile it is often lacking in information and content, also the low price of the parts can be tempting. Just remember the old adage, "If it seems to good to be true, it probably is....".4 points

-

I agree, from my time on the committee I know how difficult it can be to get members more active. What I find had to believe is that members aren't coming forward to take FREE MONEY FROM CLUB FUNDS to put towards local events. It will only takes a small amount of organising to set up a run out or meet up for half a dozen members and you could get your lunch or entry fee paid for. What are people waiting for?3 points

-

3 points

-

3 points

-

Had confirmatio from the organisers that we have a nice discrete club stand next to the castle but near the back (Square 46 on the site map). All the relevant details are in the attached PDF file. Any questions let me know. Kimbolton 2025.pdf2 points

-

Well a massive thank you to the Forum for today’s news! After nearly 6 years, endless hours of research and sourcing parts and cold nights in the garage it went in for its first MOT since 2010 and passed with flying colours, adjustment needed on handbrake as binding slightly, given stationary for so long and I haven’t gone through them yet I was pretty flawed with result. Now to get back on with new dashboard and dials, but essentially has a new lease of life ready for the roads where it belongs2 points

-

Brief update for future reference, ended up sending the clutch and flywheel to CG Motorsport - Performance Clutch Specialists (thanks Daveo). They relined the clutch and resurfaced the flywheel and pressure plate at a good price, they did a great job all came back within a week like new.2 points

-

I agree with Al that your Crank Position Sensor looks very dodgy. The CPS trace for my engine is like Al's, on and a completely solid line as soon as the engine is cranked until turned off. The fact that yours turns on and off might indicate a problem. The CPS is fundamental to the engine running. Without a cranking signal MEMS won't know the engine is turning and won't operate the coil or injectors. From my notes, here are some things to check on the CPS: - disconnect the plug and check resistance across the 2 sensor terminals, should be 1260-1540 ohms - check the plug and wiring is intact, and all connections are making good contact - check the sensor is correctly fitted over the flywheel. It's held with 2 bolts and there should be a spacer underneath to give the correct distance away from the 34 reluctor poles on the flywheel - the 2 core cable should be connected to the engine loom with a screened and earthed cable to prevent interference - the wires should connect blue +ve to MEMS pin 31 and white -ve to pin 32 (my engine wiring colours) - the blue wire should show 5v with ignition on, and then drop to 3v when cranking2 points

-

I acquired my Tiger Cat E1 in June 2024, finding it in a deplorable state. The electrics were entirely non-functional, necessitating a complete rewiring from scratch. The dashboard was riddled with holes and filled with inoperable instruments, while the engine cooling system was severely rusted, rendering the car undriveable. Over the next three months, I dedicated myself to restoring this vehicle, investing over £3,000 in spare parts alone. The restoration journey was challenging and required extensive work, but it was also incredibly rewarding. A crucial factor in my success was the support and expertise I found within the RHOCAR club forums and the broader kit car community. Their advice, shared experiences, and encouragement were invaluable, providing me with the knowledge and confidence needed to tackle each problem as it arose. From sourcing hard-to-find parts to troubleshooting intricate issues, the community's collective wisdom made the seemingly impossible task achievable. Without their heip, restoring the Tiger in such a short time frame would not have been possible. The project was a testament to the power of community and shared passion, transforming a dilapidated vehicle into a fully operational car. Meet Eva, my restored Tiger Cat E1 at The Princess Royal Car Show in Farnham, Surrey on Sunday 25th August 2024, entry is Free. A_Tiger_called_Eva.mp42 points

-

Just to finish this off. My car is started and running well. Although the gunge in the fuel filter would not have helped, the main problem turned out to be the battery - which I had some doubts about! - it no longer had enough oomph to turn the engine enough, to get the mechanical pump to drag the fuel through. I have also fitted a none return valve, but too soon to tell if this made any difference yet. There were other useful benefits of this investigation and fitting seat runners: It made me spot the broken earth from the windscreen washer pump (MOT failure) It made me spot how bad a length rubber fuel pipe was - looked fine but was crumbling away - must check any hidden under the car now. Found a really easy to access and available, ignition controlled live, to power an auxiliary socket - yippee, I thought this would be a nightmare.2 points

-

Well it's now sat on my driveway having been collected last night. So many things that need attention on it but we'll start by getting the engine running (hopefully) then move on from there. Cheers Jon2 points

-

Bought it now so I expect to be pretty active on the forum in the coming months.2 points

-

Except the we will all want to know what the solution was . . . . . when it is found!2 points

-

For those following this thread, we think we have solved the problem, The failure to start was down to a weak battery and dirty plugs. Once we cleaned the plugs and added a battery booster she started OK but still died if you were a bit rough on the throttle, and ran very roughly throughout the range.. When I plugged my analysis program into the ECU it showed the Throttle Position Sendor (TPS) was not working. We tested a spare one which seemed fine. We are waiting to hear from Wayne how she runs when he has swapped them over.2 points

-

We took a heavy hit in January, losing 14 members and gaining only 3. However, we have to put this in persepective. For historical reasons we have a large proportion of our members (almost 20%) whose renewals happen on the 1st January, they also tend to be the longest serving members who are now getting too old to get in and out of their cars (I am just about hanging in there ) or have sold them. So we are still sitting with a very respectable 340+ members. So welcome to our 3 new members: Name Location Area Sec Daniel Russell Ayrshire (vacant) Stuart McHaig Newton Stewart (vacant) Tuono72 (John) Evercreech Robbie2B2 points

-

Here's to all you tinkerers, drivers and skivers . I wish a happy and productive new year and a hot blazing summer to you all Andi2 points

-

2 points

-

Hi all Those of you who opted to have the magazine delivered in PDF format should be receiving it now. If anyone who thought they opted in does not receive it by tomorrow please let me know. Al2 points

-

Hello everyone, I wanted to share my journey of restoring my Tiger Cat E1 kit car, which I’ve named Eva. I’ve documented the entire process on my blog, and I hope it can inspire others who are interested in project cars or looking to take on similar restorations. From tackling extensive rust issues in the cooling system to refurbishing various components, I’ve chronicled each step of the journey, including the challenges I faced and the lessons I learned along the way. You can check out the blog here: A Tiger Called Eva. I’d love to hear your thoughts, and if you have any questions or tips, feel free to drop a comment! Looking forward to connecting with fellow car enthusiasts! Cheers, Thanasis2 points

-

You'll always be taking a chance on the weather in September but we got lucky today. No rain and even a bit of sunshine. We probably went a bit further than we needed to by going as far as Barmouth but it was worth the effort for the ice creams and two of us getting shat on by seagulls.2 points

-

I’ve just posted out the latest edition of the magazine to all those members that agreed to an electronic delivery. If anyone who opted for that route has not received the magazine please let me know (after you have checked your spam folder )2 points

-

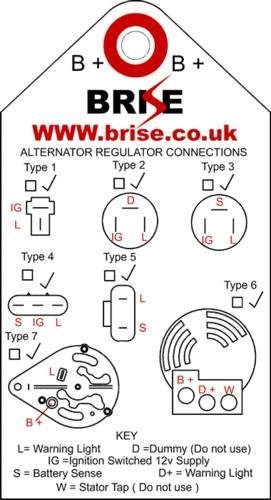

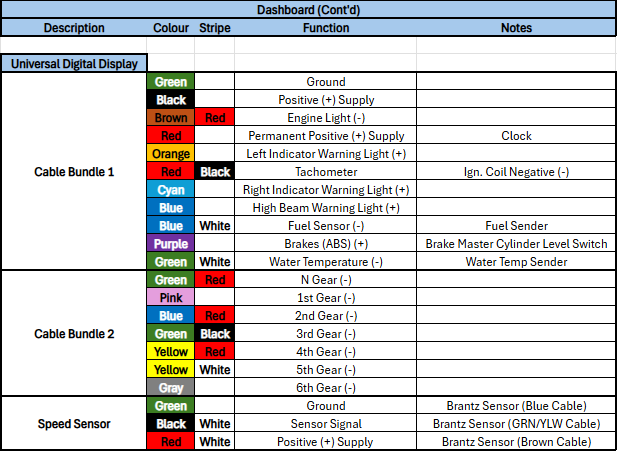

If you're looking to upgrade your kit car dashboard with a budget-friendly digital speedometer/tachometer, this guide is for you. I recently installed a basic Chinese universal speedometer/tachometer, and while the instructions were less than helpful, I've managed to get it working perfectly. Here's how you can do it too. Where to Buy I purchased my dashboard from eBay for around £30. Similar models are available on AliExpress and other online marketplaces. AliExpress Speedometer eBay Universal Speedometer Issues and Solutions 1. Water Temperature Sensor The manual specifies a 900-80 Ohm sensor (Cold-Hot), but this didn't work as expected. At ambient temperature (20°C), the dash showed 2 out of 5 bars, and at 85°C, it maxed out all bars. Solution: Use a resistor in series with the sensor to increase the resistance. Calibrate by using the sensor that gives a maxed-out reading at operating temperature, then adjust with a resistor until the dash shows 3 out of 5 bars. 2. Fuel Sensor The manual calls for a 0-90 Ohm sensor, which can be hard to find. Most available sensors are 0-190 Ohms, which won't work correctly. Solution: Purchase a 0-90 Ohm sensor that fits your tank. I found one on eBay: 0-90 Ohm Fuel Level Gauge Sender 3. Speed Sensor The kit includes a magnetic speed sensor but mounting it can be tricky. Solution: Use a Brantz Motorsport Speed Sensor, which connects to the gearbox speed cable and sends out 4 pulses per rotation to the dash. This allows you to calibrate the digital dash to match your original speedometer. Brantz Motorsport Speed Sensor Installation Tips: Water Temperature Sensor: Install the sensor as per the manual. Use a multimeter to measure the resistance at different temperatures. Add a resistor in series to adjust the resistance until the dash displays correctly. Fuel Sensor: Ensure the sensor fits your tank. Test the sensor before installation to confirm it works correctly with the dash. Speed Sensor: Attach the Brantz sensor to your gearbox speed cable. Use a cordless drill to simulate speed and calibrate the digital dash to match your old speedometer. Wiring Matrix: Final Thoughts After overcoming these issues, my new digital dashboard is fully operational and looks great. I hope this guide helps anyone else looking to upgrade their dashboard with a budget digital speedometer/tachometer. Feel free to ask any questions or share your own experiences!2 points

-

2 points

-

Good drive out today. Jez drove up from Coventry and met me in Tamworth. We headed to the Ponderosa Cafe near Llangollen via Whitchurch. When we got there, we met Ian and Joy who'd come down from Warrington. We all then went via the Evo Triangle to Llyn Brenig where we had lunch. After lunch we did a refuel stop in Denbigh from where Ian and Joy headed back while Jez and me went back home via the Evo Triangle, Bala and the Berwyn mountains. All in all, probably 260 miles. Roads were a bit busy in places but at least it keeps your right foot in check.2 points

-

I'm planning a run out on Saturday 14th September. Destination to be decided but most likely to be either mid-Wales coast or North Wales, it depends on who's attending and where they're travelling from. I plan a full day, so leaving Midlands before 9 and arrive back later afternoon.1 point

-

1 point

-

If you're not already aware, make sure that the raised pip on the back of the inner brake pad aligns with one of the cut outs in the caliper piston. It stops the pistons turning so the self adjuster works properly but more importantly, if it isn't aligned, the pad doesn't will tip as the piston moves and will wear unevenly.1 point

-

1 point

-

1 point

-

Ok so managed to do a conversion to rear discs with an eBay kit and surprisingly it was bolt on without any modifications! — Never had that before with an eBay bolt on kit! If anyone else is interested for a bolt on rear disc conversion kit for a Tiger Cat E1, I have attached the kit link below. https://www.ebay.co.uk/itm/3056756948701 point

-

1 point

-

Looking good & a very useful write up. If it was my car I think I might have to go for a slightly larger steering wheel1 point

-

Welcome from me too - great to see our newest area secretary has got 3 new members already Also nice to see a new member close to myself. Steve1 point

-

1 point

-

1 point

-

1 point

-

ditto, that's what I am trying not to have to do lol but if I cannot get it to work that be my option too.1 point

-

Hope you get it sorted I having a issue with escort rear drums at minute with them binding on passenger side after replacing everything on them. I also had to hunt down new handbrake bracket for mine. I could not buy one new had to get some 2nd hand ones.1 point

-

Hi all I hope to be with you all on Tuesday, Just getting used to being part of a crowd. Its good to see so many members turn up. Take care Allan1 point

-

No news yet Alan, so hopefully all being well ill be there. stay safe the lot of yous Harry1 point

-

I'm planning on going up to North Wales on Sunday 21st July. The NW guys made mentioned they were going down to Bala on the same day, if they do, we could maybe meet up. My plan is to set off early (0900ish) and head for the well known Ponderosa Cafe on the Horseshoe Pass near Llangollen then maybe do the Evo Triangle. People that know me, know I don't bother with maps in North Wales so the route can be adapted to suit. I'll share this on my Midlands area WhatsApp group and post any updates here, I know @Jez Morton has said he's interested.1 point

-

There's clever with the picture I'm sure I'll be there, but I'm not sure what I'll be driving In fact, the way things are going I might come on the bus1 point

-

Great run out. Daughter also enjoyed being a passenger for once.1 point

-

1 point

-

Another cracking day, gorgeous driving weather. Burghley House is a great place to visit with plenty to see and do so is very popular. The big attraction for us is that they don't pay for parking, they charge only for the house and gardens. Even though the children are still at school (I think), the place was packed and the car park was full. But we found a nice spot in the overflow car park And as the old saying goes, "It's not the quantity that matters, it's the quality" Great day1 point

-

Damn, that is sad, especially in the Midlands where so many of our members are. This is part of the reason why I recently sold my kit - there is no-one down South who seems interested in meeting up. I don't mind driving on my own but, occasionally, it would be good to meet others. I regularly see kit cars out on their own but they are mostly Caterham's who probably wouldn't be on here anyway. TBF, it's pretty much always been like that down here - sad to see it spreading up north though.1 point

-

I was really looking forward to this show and all was going well until somewhere past Uttoxeter when the car developed a scary noise from somewhere under the bonnet (I think) every time I decelerated. It sound like something has broken and was rattling around but, having driven back home slowly, I spent several hours in, under and round it NOT finding anything !!! I now know exactly how to get it to make the noise but I still have no idea of what it is. I'm sure this will probably make a good story when I finally fix it.1 point

-

Very good shout! when I bought the car 2 months ago, it was overheating and had air lock issues with the cooling system and thats exactly what I am doing, I have replaced the whole of the cooling system and got distilled water and Prestone Coolant Flush, running it through and changing it, water comes out brown but it is not as bad as the first run!1 point

-

I'd recommend you put a bit of grease on the drill and then any "bleep" will stick to the drill and not drop into the waterway.1 point

-

Rust in the head. How far can in can you push a 7mm drill? Is it far enough to take the new sender? If so you could use a 8mm drill bit turned by hand to clear the *bleep* out.1 point

until