-

Posts

2,008 -

Joined

-

Last visited

-

Days Won

60

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by alanrichey

-

Same here. I started to see excessive wear on the outside of the front tyres so had it checked at the local garage. Like you I had too much toe-in. Now corrected, and although my self centering was OK before, now it is quite aggressive and I have to keep a lot of pressure on the steering wheel during turns. But now extremely stable in a straight line. Just have to keep an eye on the tyre wear to make sure it is fixed.

-

I have separate relays for the hazards and the indicators. A couple of years ago I had the same problem as you, indicators not working while hazards were fine. It turned out the indicator relay had got wet after I washed the car. Thought I was clever by putting it inside a plastic bag to protect it, turned out to make it worse as condensation occurred inside the bag and soaked the relay again Once I figured out the water was leaking in from the windscreen wiper spindles I solved the problem by moving the relay to a safer place.

-

After 3 very successful meetings in April I am looking to do the same for May using my usual format, i.e. a nice drive then a picnic lunch at some beauty spot. The first one, subject to weather, is going to be a mid-week run to Foxton Locks (highly recommended, large car park and a nice walk along the locks). This one will still be limited to 6 people and at the moment is fully booked with my regulars, although I am happy to have reserves if someone drops out. The next one will be after the 17th, when up to 30 can attend so we won't be limited. Haven't decided on the location yet, but if anyone is interested let me know. I'm happy to make it a weekend if that would help anyone is still working and can't do mid-week. Al

-

I don't pretend to be an expert on this, but as I understand it for the IVA/MOT you need to ensure the front brakes lock up before the back brakes. In the semi-standard kit car fit with discs at the front and drums at the back this happens automatically. But if you fit discs to the back don't you have to add some sort 'brake balance' system to try and get the brake action loaded towards the front (70:30 rings a distant bill). Just some thing I have picked up over reading the forum for the last few years, happy to be corrected.

-

Does seem to be a bit excessive, maybe the voltage regulator (which also converts the AC to DC) is playing up. Can’t explain the voltage not dropping off.

-

My indicators don’t auto cancel so I spent a lot of time driving with the indicators on. So I fitted an industrial strength buzzer (I am told you can hear it from 50yds away) and a high intensity LED right in my eyeline. Result, no more driving with them on. In fact my MOT tester said they were the best he had seen The only downside is that they draw so much current that if one of the main bulbs fail there is no indication as there is with a normal setup where the indicators go double time.

-

Yes, with the engine not running the battery voltage is about 12V, once the alternator kicks in the voltage should be 13.5.-14V. Going off while cranking is normal, the system will switch non-essential stuff off to ensure full voltage to the starter motor.

-

As I understand it, one side of the bulb is wired to the 12V ignition supply and the other side to the alternator. So when you turn on the ignition the bulb as 12V on one terminal and 0V on the alternator side do it lights up. At the same time the current flow goes through the alternator exciting coils to earth. Once the engine starts the alternator starts up and puts 13V+ onto the other side of the bulb, so with only 1V across the bulb it goes out (probably also has diode in the circuit to eliminate any possible flickering at the low voltage). So if your light is not coming on when you switch on the ignition then either the bulb is not getting a 12V feed (which I think you have checked) or the feed from the alternator is not 0V. If it is wired to the correct terminal on the alternator I would think it is an internal problem with the alternator.

-

Beautiful day for a run out and picnic. Just a select few, with even the cars doing social distancing Thinking of doing it again on Thursday, one slot still available.

-

Had a practice run to Burghley last week which worked out well so having the second meet tomorrow. Again, 12:00 at Burghley House for a lunchtime picnic. Weather looking perfect. So far we have 4 attendees so still have 2 spaces left if anyone wants to come along and join us.

-

Now we are released back into the community, time to start getting together again. I'm going to run at least a couple of my usual picnic lunches either at Burghley House, Rutland Water or one of the local County Parks. Obviously limited to 6 people, so if anyone wants to come let me know your availability and if you will be accompanied and I will try to work out a programme.

-

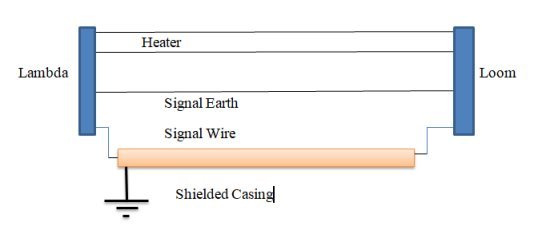

I think actually have a slightly different wiring setup to Andy so I'll let him comment on his. As I see it, on his diagram he has both the signal & earth (Black/Grey) inside a shield. I actually have them totally separate and keep them physically apart, and in turn physically separate from the heater wires. So only the signal wire is a shielded cable and the shielding is earthed to the chassis at the Lambda end and NOT connected at the loom end. I suspect both methods are OK, but all I can say is mine works

-

I can't do one close to the pump, it is mainly within the engine block. But it makes sense to put one at the point where I disconnect the hose at the top of the radiator. Would be easier to bleed the system regularly,

-

Sorry, don't understand the question.

-

Just to close off this thread, the problem has gone away, but I have little or no idea what caused it in the first place. I checked all the component parts and everything was working as advertised, but still no apparent circulation. So I took some hoses off and reverse flushed the whole system. But nothing came out that might have caused a blockage, every part of the system was clear. I then refilled the system, but using a slightly different method than before, by removing the pipe that goes from the original heater feed to the top centre of the radiator (A Superspec feature , and the highest point in the system) while the engine was running, topping it up as required until all the air had bubbled out. Reconnected the pipe then ran the engine, the temperature climbed up to the early 80s, at which point I felt the top pipe warm up (I have an 82C thermostat) then at exactly 95C the fan kicked in and the engine cooled off to 91C when the fan turned off, then the cycle began all over again. A decent run out (Legal, as I was picking up my medication, although I would be hard pressed to explain why I covered 24 miles when the pharmacy is only 1.5 mls away ) showed she actually stabilised nicely at 84C and the fan wasn't needed. So I am a bit frustrated. The only think I can think of that makes any sort of sense is that I had an air lock that had migrated to surround the water pump with air, thereby stopping any circulation. It is an unfortunate design problem with the Rover engine that those engines destined to have an air conditioning pump fitted have a redesigned water pump attachment that means it sits at the top of an inverted 'U' so an air lock could form around the pump. I'm quite pleased to have discovered a much better way of filling the cooling system that just about guarantees no air locks. You would think after nearly 8 years with the car I would have figured that out earlier.

-

I have cut mine so they fold horizontally along the bottom of the clear Perspex. That way they fit behind the seats.

-

Some people I know forget to take photos of the parts that won’t be accessible at the IVA. Lower seat belts mounting spring to mind.

-

Like Kevin I cut my vent holes with an angle grinder and a 1mm disc. Very straightforward.

-

The Superspec has 2 independent temperature sensors, one for the gauge and one for the ECU. The ECU feed gives me an exact temperature reading, and over the last few years I have been able to use that to calibrate the gauge. Before this event I could see that the fan switched on at 95C, which equates to the ‘O’ of the word NORMAL on the gauge. So these 3 independent sources give me a very good handle on how the cooling system I’d doing.

-

Trouble is I can’t guarantee the water pump has failed. As you know, on our cars the belt pulley drives the power steering pump which then drives the water pump. So the problem could be anywhere in the train. When it warms up a bit I will be investigating. I’m hopeful it isn’t the head gasket, as there is no loss of coolant and the oil is still clear.

-

Always a possibility in the weird Superspec cooling system design, but I did everything to get rid of any air. And this was a sudden occurrence after 2 years of working perfectly, so I think it's safe to say something has broken.

-

Thanks for that. No heater fitted so that isn't a problem.

-

My cooling system has raised it's ugly head again. I was driving along quite happily when the temperature suddenly jumped to 110°C and stayed there. Oddly my fan (the 95°C, thermostatic switch is in the top hose) did not come on until about 10 minutes later. My first thought was a jammed thermostat, but having removed it the symptoms were still the same, a quicker than normal warmup finishing up well above 100°C. Next I checked the coolant level and that was normal, although a small amount had come out of the pressure cap and into the overflow bottle. The fact the 95°C fan does not trigger until 10 minutes after the engine had got to over 100°C seems to show the water around the switch is getting hotter by just normal conduction rather than circulation. I think I confirmed that by removing one of the hoses and putting the end in a bucket and even after the engine warmed up there was no water coming out. So our (I was working with AndyW) thought that it must be either a failed water sump or a blockage. There was no noise coming from the pump and the auxiliary belt was working perfectly so if it is the pump it must be the drive shaft that has failed. I am going to do a reverse flush of the system when it gets a bit warmer outside (there is no rush to fix it) to check for a blockage, but wondered if: a. Have I missed something, could there be another reason ? b. Is there a definitive test I can do to prove there is no circulation ? c. Rather than try and replace the pump (notoriously difficult on the Rover T16 as it is built-in with the Power Steering pump) could I just fit an electric pump in the bottom hose ? Has anyone fitted one to their kit ? Did you have to remove the original water pump (I guess if it is jammed it would cause a blockage, although a reverse flush should show if it has jammed) ? Grateful for any thoughts on the way forward. Al

-

I’ve also noted that when I was a young lad (many years ago ) car batteries used to gracefully degrade and give you plenty of warning of impending failure. These days they seem to fail catastrophically overnight with little or no warning. I’ve also just had to replace mine as 24hrs after a full charge it wouldn’t start the car.