-

Posts

8,200 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Longboarder

-

Hazards have a battery live supply. Indicators have an ignition live supply. So possibly the indicator supply has failed by fuse or wiring or the mechanics of the switch have failed.

-

Still thinking about the apparently poor spark. You have the right coil for the accuspark dizzy. Are both getting good clean 12v supply. Might be an idea to confirm this by rigging temporary flying leads, one direct from battery positive to the + terminal on the coil and the second to the + on the accuspark accuspark. This is to cut out any imperfect wiring in the harness. Then start her up and run as normal. Note, you may not be able to switch off without pulling the + lead off the coil. If the misfire is still there after a decent test then you know your car engine loom is OK.

-

That seems like a reasonable explanation and it was happening both before and after the rebuild, suggesting the rebuild has not addressed the problem. Now you could be pumping excessively to fill the rocker cover or the draining is restricted in some way. Long time since I gazed at a pinto head with the rocker cover off. The engine has to be level for the oil to reach the drain holes. The holes must be open and unobstructed. A nut or bolt could easily find its way into them without passing through and cause an obstruction. Any missing? Can't remember where and how many there are but I would have the rocker and sump off and probe each drain hole with a magnet on a telescopic rod, them a wire coat hanger and a bottle brush to ensure they are clear.

-

Just in case, have you checked the strength of the spark on the other three plugs. Might not be as localised as it seems and they might all be weak and cylinder 4 (possibly the least efficient mechanicaly due to wear, sticky valve or whatever) just the first to show the problem.

-

They are usually shown as the pic below. Split system, tandem pistons, pressure reducers? on rears. Intended connections are one front and one rear to each piston and thus equal displacement for each piston (near as makes no odds). You have one piston working two disc calipers for the fronts (lots of fluid) and one piston working two drum slaves for the rears (little fluid). When the piston currently feeding the rears has shifted its fluid and the rear brakes are hard on both pistons stop. Quickest check for this is swap the rear and one front connector on the master cylinder and bleed then try the brakes. Volumes each piston needs to shift would be closer but not equal so watch out for uneven braking, pull to one side etc, but I would hope more effective braking. Don't know if you need to use the reducers or not. First try without but be careful. If so then I would re-plumb with the pressure reducers going to the rears as indicated so the MC works as intended. Yes you would need two lines to the rears. Benefit is the safety of a genuine split system.

-

I think an air lock is unlikely if the pump is giving 8.5 bar. That's enough to purge any air and yes it will purge through the injectors easily. You can confirm that the pressure regulator is on the fuel rail outlet and not at the input end? Fascinating (and handy) that the fault is so repeatable. Then in use for your fuel pressure to fail something goes beyond its weakest point. I suspect the fuel pumps ability to suck is its weakest point. Replace the low pressure pre-pump filter with a cheapo £1 ebay see through plastic one or even temporarily test run without it if your fuel tank is clean enough. My first thought was fuel filter clogging and collapsing and the pump failing to suck through it. Release of hose at rail allows slight back flush to slightly clear the filter. Air (if it enters) enters between LP filter and pump. If it's not the filter then something in the tank blocking the outflow. Other thought was tank vacuum but you say no. No this doesn't explain why touching the inlet hose is a problem and may not explain why releasing it cures it temporarily. I take it you have examined those joints and the holes are unobstructed. Would be usefull to know what the fuel pressure gauge reads when the engine stalls.

-

In the traces above is the pale blue line revs? If so, should it not be continuous? Crank sensor problem?

-

Sounds like an air-lock. Worth checking the stat to make sure it has a hole and jiggle pin to assist air bleeding. Easy on the zetec as it's just three screws.Make sure you refit with the jiggle hole uppermost. The run the engine up to temp plus ten minutes with the rad cap off and keep topping up. Then refit rad cap. That will usually shift air. Sadly I have warped one zetec head by boiling it when I had a hose rip.

-

To replace kit car dampers the first and most important measurement (which the supplier won't have) to take is the length, eye to eye, when the car is at its normal ride height. You can wind down the current spring platform positions and then jack up to get the ride height to what you want it to be. This gives the supplier the running length of the shock and allows them to select a shock that roughly has two thirds of its movement for compression and a third for extension. Spring rates are affected by corner weight and shock angle mostly and will be individual to your car. For a series 3 with almost vertical front springs about 100 to 120 I would guess. Rears about 300 if in the centre of the trailing arm pans but 230ish if from the original shock mount, assuming they are close to vertical. More if angled.

-

Just to check you are not using a facet style square block LP pump with bullet filter are you? As shown below. These bullet filters are infamous for wierd fueling problems. Pumps are OK ish, used with a £1ebay simple plastic paper filter.

-

And it's a new series 111. Would also suit anyone with a very tatty or bent series 3 or new 111 who wants to rebody.

-

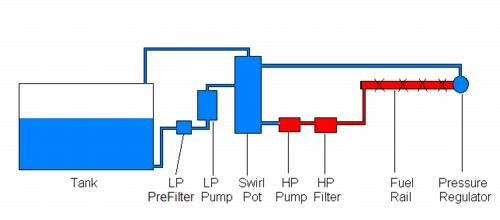

Did you get round to fitting a fuel filter after the HP pump? That was something left over from your previous thread, along with the custom map. You still running on a generic map? Have been reading your blog. Good read. DB4 GT Zagato still my favourite car. Going back to basics (but I'm still tending towards ignition), can you detail your fuel system. What pump do you have for LP/what LP filter/swirlpot/HP pump/filter/Fuel rail/pressure regulator. Can you draw up the circuits like below (which is mine and fairly typical I think).

-

Why not purchase an adjustable clutch cable (Escort), fix the quadrant permanently to the clutch cable and do away with the auto adjustment. Having said that my auto adjuster worked just fine and always did (once I worked out how it was supposed to work). It is worth wrapping insulating sleeve round the clutch cable and further binding it in copper wire for heat protection. Escort cable is

-

Most aftermarket ECU's have a battery voltage compensation table, able to make appropriate injector duration changes dependant strangely enough on battery voltage. Your fuel pump should have a wide excess supply margin and be working well within your engines needs even at 9v so I doubt its poor fuel supply if the engine is able to crank.

-

How is the pump relay controlled? (You need to know this so you can track all components and wiring that control the pump to locate the fault.) Most ECU equipped cars have the ECU switching the fuel pump relay. Some cars might have the fuel pump relay directly switched by 'ignition on' but would need to have a safety cut-off (oil pressure or impact relay are common) in case of crash.

-

Charging voltage varies but 14.2 plus or minus a couple of points seems about right to me. 13.9 should be OK. Over 15 is too high! My thinking was your battery has little reserve if switching on just ignition which can only be running coil, ECU, dash and fuel pump(s) only leaves 12.3 at the coil. Maybe you should check the wires, supply from battery to ign switch or ignition relay to the coil to make sure you have no high resistance joints all the way.

-

Just switching on the ignition knocked 0.5v off! That sounds like a pretty gutless battery to me (or poor wiring to the coil pack). And why did it need charging in the first place? Rig up booster cables from your tin top to the hood battery and repeat.

-

I think your car is a New 111. Best and last of the mono cars. Not just a series 3. And it's a bargain. IMO

-

Happening right now, 11.00 Tuesday. Just lessening at the moment.

-

Looking at your wiring diagram, no power to the coil also means no power to pin 2 on your ECU and no power to pin 20 on your dash as both those are fed from the coil positive. So you have a break between battery pos terminal and the coil positive terminal. Prove the segments of this circuit a bit at a time. Is there continuity between batt pos term and ign switch pin 1. Looking for wire failure or blown fuse between these points. Is there continuity through the ignition switch to pin 4 when the key is turned on. (Could be a failure of the ignition switch). Is there continuity from ign switch pin4 to coil pos. This last only if the wire goes direct from pin 4 to coil pos. Sometimes a builder and most manufacturers put a whopping (say 80amp) relay in, operated by the output of pin 4 to supply all the ignition live circuits (which would include dash, coil, ECU, wipers, heater,etc) so the green wire to the coil may not come direct from pin4 but may instead come from pin 87 on a hidden heavyweight relay.

-

Red herring. Probably to the rev counter as you say. Another thought. Do you get warning lights on the dash? All there? Oil light goes out when cranking? Rev counter registers? Disconnect 18 anyway in case its blown through to earth via the rev counter. (Thinking: when you wrong plugged it something in the dash got 12V it wasn't expecting or able to cope with. Hence the spark.) Did you wrong plug when the ignition was on ( If so the spark might be unimportant or very important.) or did you get a spark when you switched ignition on after (in which case the spark is vital)?

-

I hope it's just the impact switch but if not...... Could you make a list of what is working when you switch on ignition? Wipers, indicators, heater, dash warning lights, dash illumination, dash gauges, main and side lights, brake lights, etc? Absolutely everything you can think of. Can you then go through the relays and coil with a multimeter or bulb to see if you have power to coil positive, 30 and 86 on the ECU relay and 30 and 8* on the fuel relay. A what's it for question. The connection from coil negative to 18 on the instruments? Who puts anything other than a switching wire on a coil negative?? Can you take it off the coil neg and do something else with the wire from18 on the dash?

-

I think you have a missmatch there. Never come across that combination before. From my own experience. The zetec friction plate is thinner than the sierra one, the zetec pressure housing is again thinner than the sierra one. Using zetec 1.8 plate, zetec housing and cct133 works (But slips at about 160BHP) or redrilling the flywheel for sierra plate, housing and cct132 also works (And takes more torque!) and is what I currently use with uprated organic plate for 200bhp with no slip. All the five speed sierras (1.8, pinto, DOHC, CVH) used a 25.4 x 23 spline. So did a lot of the MK1 Mondeos. Most zetec Focus didn't. I suspect your combination just bolts up solid with no free space to allow the clutch to disengage. Your cheapest option is just to get a 1.8 Mondeo 1 friction plate and swap out the sierra plate. Quinton Hazel part number C1189AF should do fine. It's for MK1 mondeo 1.6 & 1.8. 220x25.4x23. (You can use all the other existing bits and you don't need to change the pin.)

-

Took these pics when I did mine. Can't believe it was 13 years ago. I added one C clip and found the throw was right for me. Clearly you can add several to taste. And yes, chopping board for spacer, cut to shape. Spacer thickness and distance the 'half ball' is moved must be the same or the gear change may be pants or stuck!

-

Having a constant earth on the negative/switching side of the coil will work fine. No sparks. Very little risk to the coil but it could overheat if ignition was on for half an hour. Still mch cheaper than having the car stolen.