-

Posts

8,200 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by Longboarder

-

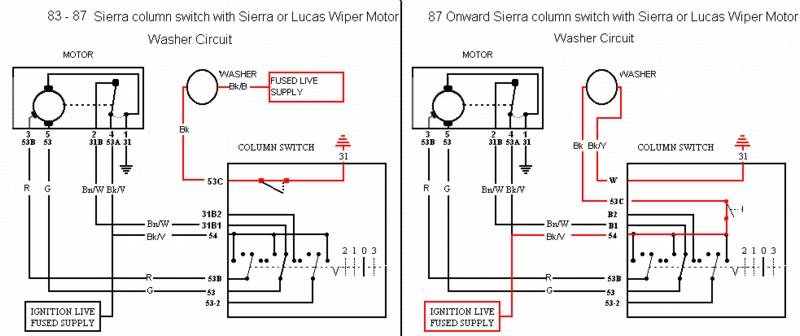

Not looked at the old diagrams in fault finding detail in ages. The latest stored diagrams are from 2006. Will put both 83BG and 87BG pics up. As you have ignition lives to both stalk and motor but it runs constantly even if the one on the motor is removed I would think that proves the motor is OK and wired OK. That leaves the assumption that there is a live input whenever the ignition is on into pin 5 onto the motor regardless of the wiper switch position. Therefore either there is an odd ignition live in the loom feeding that wire somewhere in the loom between the switch and motor or the wiper switch is faulty and feeding that wire even in the off position. You can trouble shoot by disconnecting the plug from the column switch, ignition on and see if you still have 12v at the end of the wire at pin 5 on the motor. If you have then its a loom short between that wire and an ignition live. If however there is no 12v at the pin5 wire then the fault is in the column switch and output terminal 53 is getting connected to terminal 54 constantly within the column switch. Remove the column switch and test the pins. With the wiper switch OFF pins 54, 53B and 53-2 should be isolated. 53 and B1 should show they are connected to each other in the off position In slow position 53B, 53-2 and B1 isolated. 53 and 54 connected. Fast position 53, 53-2 and B! isolated. 53B and 54 connected.

-

As above. The fueling of a DGV is affected by fuel level in the float chamber. Too high and the engine runs rich. So set the float level correctly and make sure the needle valve is not leaking. Then feed it at the correct fuel pressure. To high a pressure can overcome a correctly set needle valve and float and overfill the chamber. Ideally use a low pressure/high volume rotary pump with output in 2.5 to 4psi max, not more. Pulsing electric pumps like the Facet square block type can upset webers and I hate them with a vengeance anyway! Using a higher pressure pump and then having to fit a 'regulator/flow restrictor' doesn't make sense. Once you have the engine running with correct stable float level the carburettor adjustment screws start working.

-

Well done on the steady commitment. Looks VG. Couple of adjustment points to bear in mind on suspension. The 'floor pan' line should be slightly higher at the back than at the front. Your pic suggests it's currently slightly higher at the front. Shocks should be at rest with two third of their piston shaft exposed as a starting point. i.e. if the shock has a piston shaft that allows three inches of movement, meaning shaft invisible when fully compressed, 3" visible when fully extended, then at rest you should see two inches of exposed shaft. This is to allow adequate shock extension and compression available so suspension movement is controlled, not on the bump stops. (Does require you to have the correct length shocks for the car.) Corner weighting is a refinement for later but is more about getting the sum of the diagonals closer to equal than each side equal. All done loaded ie one or two passenger weights in the seats half tank of gas and the car rolled on the level to settle the suspenders. Although it is important that it looks nice it's more important that it works nice with these cars.

-

OMG. I can't believe it. I enjoyed the pleasure of a stay with him and Gemma way back. He got me into fitting an ST170 in place of the blacktop I had in at the time. I shall never forget the drive back from his with the top down in the sun, accompanied by a red kite for about 20 miles. R.I.P. old friend. Love and condolence to the family.

-

Yes you do but it's primary purpose is not as a shim but to stop debris getting inside the bellhousing so sometimes called a crud plate. You can adapt the one from the pinto as shown below.

-

Flush with the rear face of the crank, not all the way to the bottom of the hole in the crank.

-

Usually needle roller and there is a tiny lip seal in it. Gently taps in with a 'same size' socket and the seal is last in. The seal should be nearest the gearbox, not nearest the crank but that's only if you have OCD. Probably doesn't matter.

-

Retest fee is smaller. £40 I think.

-

Can you give more details of the car. Year, engine, model. I can have a good look at the wiring diagrams. After a quick look at the basic Mk5Golf+ the earthing of indicator bulb is shared with the main beam and side light bulb from the 10 pin plug on the headlight, back into the car loom. Thus if side and main beam lamps work normaly that rules out earth from plug to car. There is the two black wires within the headlamp unit which go from plug pin9 to the ind bulb and back to pin7 which you need to look at. These could be faulty at either end. If OK then you need to look at supply from the onboard supply control unit under the dash, and it shouldn't be hard to check the wire from that to the headlamp plug. I can get more info if needed. My wiring diags are for left hand drive vehicles so some side to side swaps of numbers/connectors/pins might be needed or guessed. (For instance front window motors are reversed but door locks are not)

-

Fair enough. We agree to differ.

-

JC. What a silly rule. Are we really saying you can't play unless you pay. Another way of putting it is that all the diagrams, knowledge and advice I have posted over the 16 years I have been a member can now only be bought by those who it might help. I don't pay my membership to read the website. I pay it because I want to be a member of Rhocar, the club and for the friends/acquaintances I see at the shows. The internet should stay free. Welcome to 2019. Dinosaurs not welcome.

-

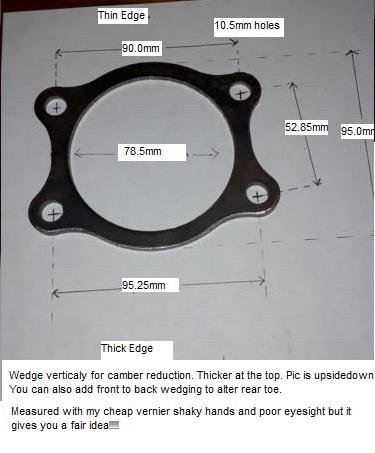

Here's a quick pic of some old ones I have lying around. Bought them off the vindicator stand at stoneleigh years ago so they are a bit crude. Measured with a cheapo vernier, my excuse for eyes and very shaky hands so all dimensions are plus or minus 10mm! Well perhaps not quite that bad.

-

Is the car fully built and loaded? The way the axle bolts up it should be very difficult to get significantly different camber on the rear wheels. You will benefit from camber wedges anyway so go ahead and buy and fit some, equal each side, but while you are doing that I think you must check the rear end is properly assembled. In particular that the rear of the car sits parallel to the ground and not one side lower than the other. Rear hubs properly bolted to the axle. Then I would have the springs out and check they are equal length and poundage. Then I would drive it a bit. Half a degree difference in the rears I could accept. Three degrees and something is off. Fitting different wedges, left and right, sounds wrong.

-

Surely series 2 but with the bonus of tiebars replacing the front antirollbar. Bargain!

-

So difficult. Lots of variants, transitional models and does it matter. Mine is a 'New111' (not a New3 or New 3, no such thing but it seems to be a chassis from a 3 with mods to fit the wishbones from the New111 to a 3 chassis. Possibly a transitional model or Trickey just getting rid of a tarted up old chassis. Who knows. To help with identification of model a better picture of the front suspension would help.

-

I ran my pinto which gave 130bhp on twin 40 dellortos without any problems on the mechanical pump. Electric pumps will also do the job fine. Depending on the pump output you may need a fuel pressure regulator. Whatever you do don't use the attractive looking and very neat facet bullet filter. They reduce flow too much as they get dirty. Use a cheap ebay plastic filter that you can see through, of a decent size and change it every six months. Like these. https://www.ebay.co.uk/itm/10-x-Universal-Petrol-Inline-Fuel-Filter-Large-Car-Part-Fit-6mm-8mm-Pipes/152552510806?hash=item2384d69556:g:FqIAAOSwYvFZHUG-:rk:6:pf:0 You also need to consider an impactl fuel cutoff system to stop an electric pump in the event of an accident.

-

PCV valve knackered... where is best place to get one?

Longboarder replied to agent_zed's topic in Engine

In a healthy engine the pcv just vents blowby gas from the crankcase and there isn't much, not enough to make the engine smoke. There just isn't the flow rate. Yes, you will find the pipes contaminated with oil. I suspect you have worn bores, excessive blowby gas but also excessive entry up the bores of oil, perhaps made a little worse by the re-entry of some oil vapour via the pcv manifold link. To check just block the valve open with a bit of soft wire and lead it into a temporary catch can like, say, a coke can stuffed with steel wool. Now run the car. If it still smokes it's not the pcv circuit. If it doesn't then fit up a better catchcan. And no, one of those mini cylinder filters is no good for this job. It will become saturated with oil and cease to be a meaningfull crankcase vent. -

Well done.It's quite a thing to be able to say 'I built that!'

-

I know in the past some members with 2B chassis cut the plough type cross bar out without significant loss of structural stiffness. In the even older times of monococque Hoods the antirollbar was a problem both from the space it takes up and the performance point of view. It's not a good thing to have controlling the front suspension on a light car. Far too stiff. The fix eventually from RH was a proper lower wishbone. On early mono's it was removal of the ARB and a change to a tie-bar, essentially giving a two piece lower wishbone on each side. Perhaps that's a better way to go? Mine had proper wishbones so I'm short on details but there are posters on here who did the tie-bar thing who can help.

-

There are several work-arounds depending on what you want the end result to be. Very early zetec ECU's can be used, original key fixed to the immo pickup and hidden in the car, if you have an early engine. Not much tuning possibility but can be made to run. Convert to carbs and use megajolt but emissions is a problem unless you have an early silvertop engine. You can even get the engine running after a fashion with pre zetec ford electronics but not much use except for banger racing. More information can be searched out on locostbuilders site. But for reliability, efficient running, full power from a blacktop and future tuning options you just have to bite the bullet and go after-market ECU.

-

Defeated by the member map. Its put my marker in Paignton not Plymouth and I have failed in my efforts to amend it. Obviously where my my router shows up cos google maps also think my location is Paignton.

-

Why would you put a swirl pot in the engine bay?? Apart from heat issues most pumps pump far better than they suck so their sensible place is close to the tank. If you install it wrong it doesn't work well. Therefore the system is flawed. No. The install was flawed.

-

The negatives of low pressure pump adding an extra component to fail are offset by the absolute reliability of the system in fuel supply under any conditions apart from inverted. As for extra complication? Sit down. Work out how it works. Plumb and wire it in. Stops being complicated if you understand it. Fit once and forget. Also increases fuel carrying capacity by 1-2 litres. Bonus! I swear by mine (but also occasionally at my LP pump).

-

Beautiful things but a fierce price. Half that gets you a set of DCOE style jenvey throttlebodies which are very close in performance if not looks. Ebay can be even better value if you can be patient.