-

Posts

1,003 -

Joined

-

Last visited

-

Days Won

50

Content Type

Profiles

Forums

Events

Store

Community Map

Everything posted by IanS

-

Are not most spark plugs resistor type anyway? I think that these went out of use a long time ago.

-

My reaction is to replace the yellow quadrant with the black one as this is a larger diameter thus pulling a bit more cable and getting more release on the clutch. I had a similar problem and this has been the long term cure.

-

The spindles have a black plastic sleeve that stays still with the spindle rotating within the sleeve. This was original ford. I will accept crude but a lot of robin hood design was crude. It has stood the test of time since 1997 and nearly 70,000 miles, only off the road a due to a couple of 6 month working abroad spells.

-

This is the sierra wipers as seen from outside. The arms are cutdown sierra arms. the 2 stainless bolts hold the wiper mechanism to the scuttle and sikaflex fills in the slots. Others have shown pics of BMC /Landrover wipers which use a rack and are a very different kettle of fish. pics from under the scuttle did not come out I will try again.

-

Pity that you do not have the adjustable colum from the later sierras.

-

I managed to fit the modified sierra wipers back in 1997. I sealed round the spindles with sikaflex which has stood the test of time. I did not modify the holes in the scuttle but had the spindles more upright than you appear to have yours, I cut down the sierra arms and had to strech the spring to make them work. I think that the wipe speed is just below the SVA requirement when the screen is dry but is OK when wet. I have since replaced the arms and blades as the blades died after 20 years. I will try to get pics tomorrow

-

I always thought that it was a pair of wool socks and a pair of highly polished brogues that are worn under a kilt. A dirk in the sock is optional and only to be used on an englishman who calls it a skirt.

-

I have a 1983 reg car, 2 years off tax free, Of course many years ago I had a 1973 car due under the old system to be tax free (then 25 years I recall) when historic cars got frozen at before 1971, westminster can and will change the rules to suit rasing revenue where they can, so I might not get it this time. With the advent of tax free electric cars expect the car tax rules to have a big shake up soon as more nissan leafs and teslas join the car fleet.

-

It was over 10 years ago and I appear to have lost the paperwork but I know that my springs are a bit softer at 160 lb. I also had to drill out to 1/2" this is because the smaller rubber inserts were overloaded.

-

They look like the robin hood own brand zimmerides. (did I spell that right?) I had them but replaced with Gaz. They were modified shocks from the original minis ( not the new bmw mini). RH turned a thread on steel tube with a lathe fitted with a 4 jaw chuck. The adjustable nuts are fitted the wrong way round, the thinner nut should be on top.

-

Your car is lighter than the doner cortina probably around half the weight. Top speed is a bit less as our cars are not very good aerodynamically, that windscreen is flat and fairly upright. The donor brakes were designed by ford to stop the heavier car whilst fully loaded with 5 adults and their luggage whilst pulling a trailer. In other words even driving like you stole it the standard brakes will have plenty of margin. EDIT to say they will be good if not worn out.

-

I think that the off center is not a problem. The Exmo and series 3 ( and probably more RH cars) had the engine offset a couple of degrees from straight to give more foot room in the drivers foot tunnel giving more room round the pedals. the front of the engine is nearly central but the gearbox mount and transmission tunnel is displaced left so the engine/gearbox is not strait. This does not cause vibration problems. A lot of production cars did not have a straight power line and did not have problems with vibration. I have had problems in the past with out of round tyres, easy to check, jack the wheel up and spin it whilst observing the tread of the tyre for even rotation.

-

If you want a bit more information. https://www.littelfuse.com/~/media/automotive/catalogs/littelfuse_fuseology.pdf

-

There is a pressure regulator that releases excess fuel from the fuel line back to the tank/swirl pot keeping a constant pressure in the fuel line. If it is stuck closed then the fuel line will over pressurise and the injectors will pass to much fuel. When the high pressure pump is running is fuel returning to the tank/swirl pot?

-

Length is not what matters very much. Cross sectional area and material matter, a fuse works by melting and the molten material shrinking back. Material gives restivity and CSA gives current density and hence how hot the wire gets. Material also sets the melting point. I think that only a short length of the cable is actually the fuse and the copper ends are designed with a small cross section to limit the cables ability to take heat away from the fuse section. The electrical loads can be calculated. Headlights 60W main beam 5A each 10A total (dipped is less) Side lights 5W each so 5 off (include numberpalte light) 2.5A Brake lights 21W so 3.5A total. Ignition under 4A Electric fan 5 to 10A So total load arround 30A Now for the other part what is the alternator output? as nearly full output can flow back to the battery to replace cjarge used by the starter shortly after the engine starts. The alternator output should be greater than the total of all normal loads so as to have some left over to charge the battery so worst case with the above 30A total normal load a 40A alternator would have 10 over to charge the battery with everything switched on and 36A to charge the battery with only the ignition as a load. These charge rates will only be for a short time before going into a trickle charge rate as the battery regains full charge. So with a 40A alternator I would use a 50A fuse and with a 60A alternator I would use a 70A fuse.

-

White smoke can be steam due to leaking head or inlet gasket. Was there enough antifreeze?

-

If that windscreen frame is ali I would not think that it is strong enough to take the load at speed without folding. There is a reason for the steel mount and support we have for cars fitted with a screen.

-

Another tool to do this. https://www.burtonpower.com/valve-spring-compressor-in-situ-dra57630.html As always the shipping adds a bit to the price.

-

Normal seat problem is lack of room between transmission tunnel and side of car, very few seats fit. Changing suspension is up to you to design and build as I am not aware of any upgrade kits for this.

-

If your car is like mine to remove the engine disconnecting the exhaust manifold is not enough, I have to remove the studs from the head to get enough room to extract the engine as the exhaust manifold cannot be extracted with the engine on its mounts. I have to remove the radiator to remove the engine. This gives enough room to move the engine forward releasing the gearbox input shaft. Then it is support the bell housing and remove all the bolts connecting the engine to the gearbox. from there on it is straight forward if you have removed engines from front engine rear drive cars. Refitting the gearbox use a new rear seal for the propshaft (how do I know, had to fit twice). remove windscreen if fitted and then it is posible to slide the gearbox onto the propshaft whilst juggling the propshaft end through the hole in the transmission tunnel for the gearlever. I supported prop shaft on old lifting strap and had gearbox on trolly jack kicked back with left foot whilst right hand held lifting strap and standing on right foot in engine bay, could have been a charlie chaplin film. 2 sets of hands are a real help for this

-

The sewing part is easy with most sewing machines provided you use a leather needle.

-

Unfortunatly forensic examination of the sensor is expensive and from reading Bosch data sheet they have already done this and warned about this failure mode. Keeping in a dry garage is probably best protection.

-

Third thought. Do not power the sensor heater until the engine is running as any condensation ( from a cold engine/ inlet mainfold etc. ) hitting a hot sensor can damage the sensor by thermal shock. Once the engine is running the condensation will be blown out and the header will quickly warm past condensation temp.

-

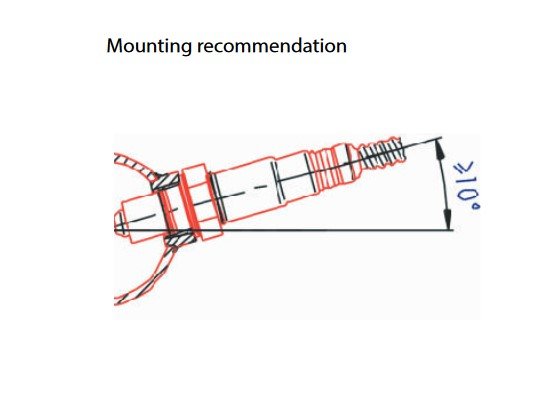

First thought is broken wire or loose connector. Other thought is that bosch state that sensor must be mounted at an angle but not vertically down so that condensation cannot form on the tip but drips off to the side of the tip. Recommended angle is 10 degree wire up from horizontal.